No products in the cart.

The Ultimate Guide to Blister Packaging: Everything You Need to Know About Retail Packaging for Effective Product Protection, Consumer Appeal, Practical Implementations & Execution

In this comprehensive article, we have gathered all the essential information about blister packaging to help you make informed decisions for your product packaging needs.

Whether you are a business owner, a product designer, or simply curious about packaging solutions, this guide has got you covered.

You can easily navigate through the 12 topics below by clicking on the section of your interest to delve into the specific aspects of blister packaging that matter most to you.

Topics Covered (click to scroll to topic):

1. Introduction to Blister Packaging

2. Types of Blister Packaging In Depth

3. Materials Used in Blister Packaging

4. Designing Blister Packages

5. Manufacturing Process

6. Equipment Used in Blister Packaging

7. Quality Control & Testing

8. Regulations and Standards

9. Choosing a Blister Packaging Partner

10. Glossary

11. Frequently Asked Questions

12. Conclusion

Let’s explore the world of blister packaging together!

1. Introduction to Blister Packaging

Welcome to the world of blister packaging, an integral element in the retail packaging landscape. This packaging solution combines the strength of a meticulously formed plastic cavity with the security of a backing card or a lidding seal, offering not just a protective shield for your products, but also an appealing display. Designed to hug the product securely within, blister packaging ensures unparalleled protection during transport, and a customer-friendly display once it hits the shelves.

Definition of Blister Packaging

By definition, blister packaging is a marriage of two critical elements – a custom-formed plastic cavity and a secure backing card or lidding seal. The result is a resilient shell that safeguards your product while enhancing its appeal to the end consumer.

The journey begins with the plastic cavity, skillfully shaped to comfortably hold the product, serving as the first line of defense against potential damage. Picture it as a custom-molded shield, offering tailor-fit protection for your unique product. Next, we have the backing card or lidding seal. Acting in concert with the cavity, it provides a robust barrier against external threats, effectively securing the product within its protective cocoon.

But blister packaging transcends mere product protection; it’s an influential marketing tool. Thanks to advancements in blister packaging machines and the availability of diverse blister packaging supplies such as blister packs & customizable tooling personalizing the packaging to reflect your brand has never been more accessible.

Furthermore, the concept of blister packaging extends to the domain of clamshell packaging. Clamshell sealing machines enable you to package products using clamshell packs offer an elevated level of protection, proving invaluable for heavier items.

As we venture further into the universe of blister packaging, clamshell packaging, and the wide range of retail packaging supplies, understanding the fundamentals of these packaging solutions is pivotal. With a clear comprehension of their advantages and applications, you’re equipped to make informed choices that enhance your product’s protection and presentation. Join us on this enlightening exploration of blister packaging and beyond, arming you with the indispensable knowledge for your retail packaging endeavors.

Common Uses of Blister Packaging

Explore the widespread application of blister packaging, a versatile tool utilized across a myriad of industries due to its superior product protection and aesthetic allure. One can’t overstate its prevalence in areas like pharmaceuticals, where blister packaging safeguards delicate items like pills and capsules. It ensures the product’s integrity while providing a user-friendly means to track medication usage. For these types of products you will need to use a clean room blister packaging machine as seen in the image below.

Let’s summarize some the key uses in common industries that utilize blister packaging:

- Pharmaceutical Industry: Blister packaging is extensively used to protect and manage medications such as pills and capsules. It ensures product integrity and offers a user-friendly way to monitor dosage.

- Consumer Electronics: Small electronics and accessories, including headphones, charging cables, and memory cards, frequently utilize blister packaging for protection and visibility.

- Toy Industry: Blister packaging is common for a variety of toys, from collectibles to action figures, offering a clear view of the product to consumers.

- Hardware: Small components such as screws, nails, and bolts are often packaged in blister packs, making identification easier and offering efficient storage solutions.

- Personal Care Products: Items like toothbrushes, razors, and makeup brushes are commonly found in blister packs, offering both protection and an attractive display.

- Pet Products: From toys to small accessories, blister packaging is widely used in the pet product industry to protect and display products effectively.

- Fishing Industry: A diverse range of fishing lures and tackles are housed in blister packs, offering clear visibility and secure packaging.

- Sporting Goods: Blister packaging finds application in packaging golf products, hunting gear, and even specialized items like duck calls.

- Cosmetics: Blister packs are popular in the cosmetic industry, housing products like lipsticks and compact powders. They offer high visibility and emphasize the product’s aesthetic appeal.

In essence, the utilization of blister packaging spans a diverse range of industries, from healthcare to cosmetics and electronics to sports equipment. With advancements in blister packaging machines and an extensive variety of packaging supplies available, businesses can effectively harness the benefits of blister and clamshell packaging for their unique products.

Importance of Blister Packaging

Blister packaging holds a dominant position in the world of packaging for an array of compelling reasons. First and foremost, it offers exceptional product visibility. The transparent blister, usually formed from sturdy PVC or PET, beautifully showcases the product, enticing the prospective buyer and boosting retail appeal.

Moreover, the design of blister packaging provides indisputable evidence of any tampering, offering consumers peace of mind about product integrity. Furthermore, the sturdy blister provides a protective cocoon for the product, safeguarding it from damage during transportation or on store shelves. It’s not a surprise then that an array of products, ranging from cosmetics and hunting products to pet supplies, have found a safe haven in blister packaging.

Blister packaging also shines when it comes to consumer convenience. Easy-to-open perforations or ‘pop-through’ designs, particularly in pharmaceutical blister packs, ensure a hassle-free experience for the end-user. Additionally, the unit dose packaging capability of blister packs, especially prevalent in the pharmaceutical sector, enhances user convenience, prevents medication errors, and assists with adherence to dosage regimes.

Let’s delve into these key points about the importance of blister packaging:

- Product Visibility: One of the core advantages of blister packaging is the product visibility it offers. The clear plastic blisters allow customers to view the product directly, which can influence purchasing decisions and reduce return rates.

- Tamper Evidence: Blister packs provide clear evidence if a product has been tampered with. It’s especially critical for products like pharmaceuticals, where product integrity is paramount. Once a blister pack is opened, it cannot be resealed, thus providing an extra layer of consumer safety.

- Product Protection: Blister packaging provides a physical barrier to the product, protecting it from external factors such as moisture, UV light, and impact during transit. The rigid structure of the blister offers excellent resistance to shocks, preserving the product in its original condition.

- Consumer Convenience: Blister packaging enhances consumer convenience in several ways. For instance, in pharmaceuticals, each tablet or capsule can be individually packed, making it easier for consumers to manage dosages. Similarly, for retail products, the backing card can provide product information and instructions in a concise, accessible manner.

- Cost-effectiveness: Lastly, blister packaging is a cost-effective solution. The materials used, primarily plastic and cardstock, are relatively inexpensive. Also, with efficient blister packaging machines, the process can be automated, reducing labor costs and improving production speed.

With the right blend of blister packaging machines and supplies, blister packaging proves to be a versatile, secure, and consumer-friendly solution. Whether it’s enhancing retail visibility, providing tamper-evidence, ensuring product protection, or delivering consumer convenience, blister packaging invariably emerges as a popular choice.

Brief History of Blister Packaging

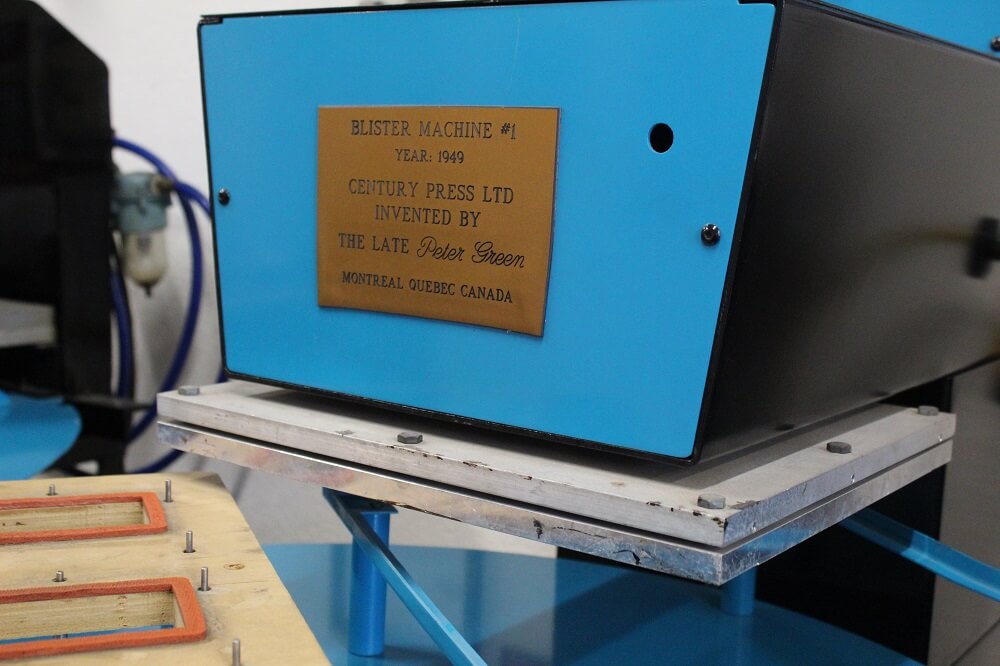

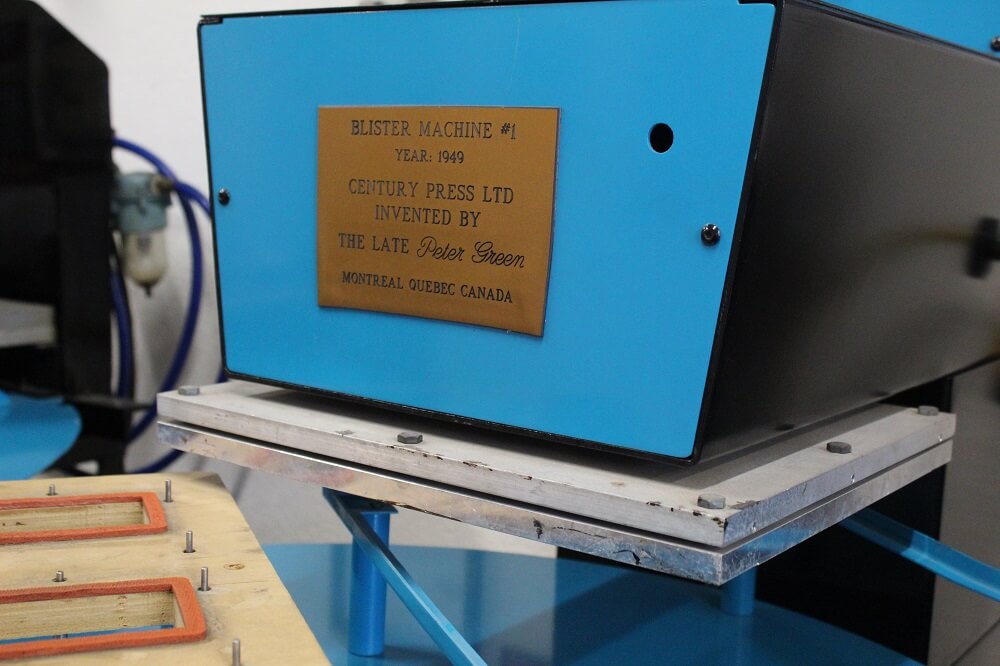

The evolution of blister packaging is a fascinating journey that begins in the early 20th century. Its birth was a response to the market’s demand for a reliable, cost-effective, and user-friendly packaging solution. What started as a rudimentary concept, focused mainly on function, has matured over time into a sophisticated blend of aesthetics, utility, and marketing prowess.

Historically, blister packaging started gaining prominence in the 1950s. The pharmaceutical industry was among the early adopters, lured by the efficiency and protection offered by blister packs. Over the years, advancements in blister packaging machines and materials led to more refined and varied designs, expanding its use to other sectors.

But the transformation didn’t stop there. With innovations in blister packaging supplies and the advent of clamshell packaging, a variant of blister packaging, the 1980s witnessed a new level of customization and durability. This era also saw an increase in the use of heat-seal coating, making the packaging process more efficient.

Fast forward to today, blister packaging has become an indispensable part of retail packaging supplies. Its applications are widespread, from packaging golf products and fishing tackle to cosmetics and pet products. Through constant innovation and adaptability to market needs, blister packaging has indeed etched a prominent mark in the packaging industry. Undoubtedly, the evolution of blister packaging is a testament to the industry’s ingenuity and its ability to respond to changing consumer and market needs.

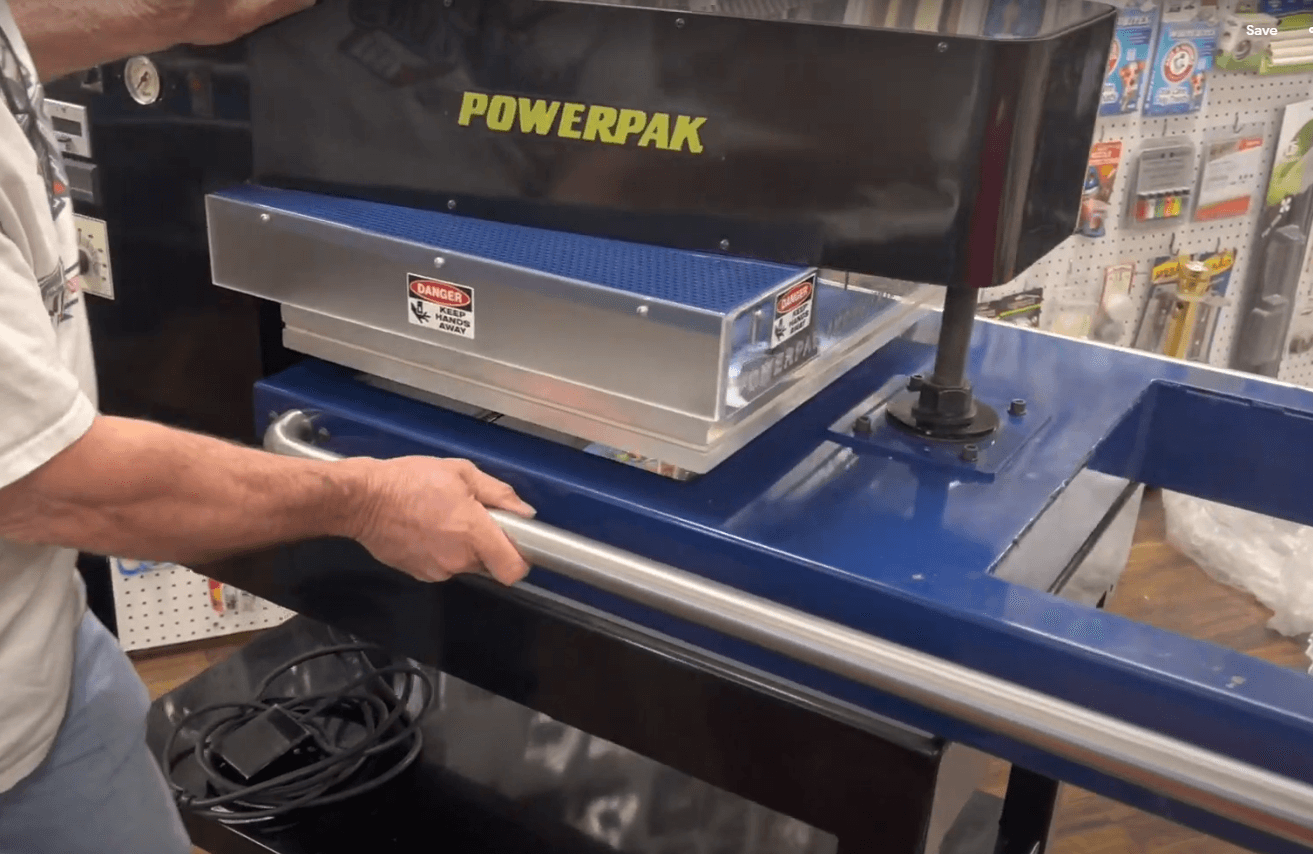

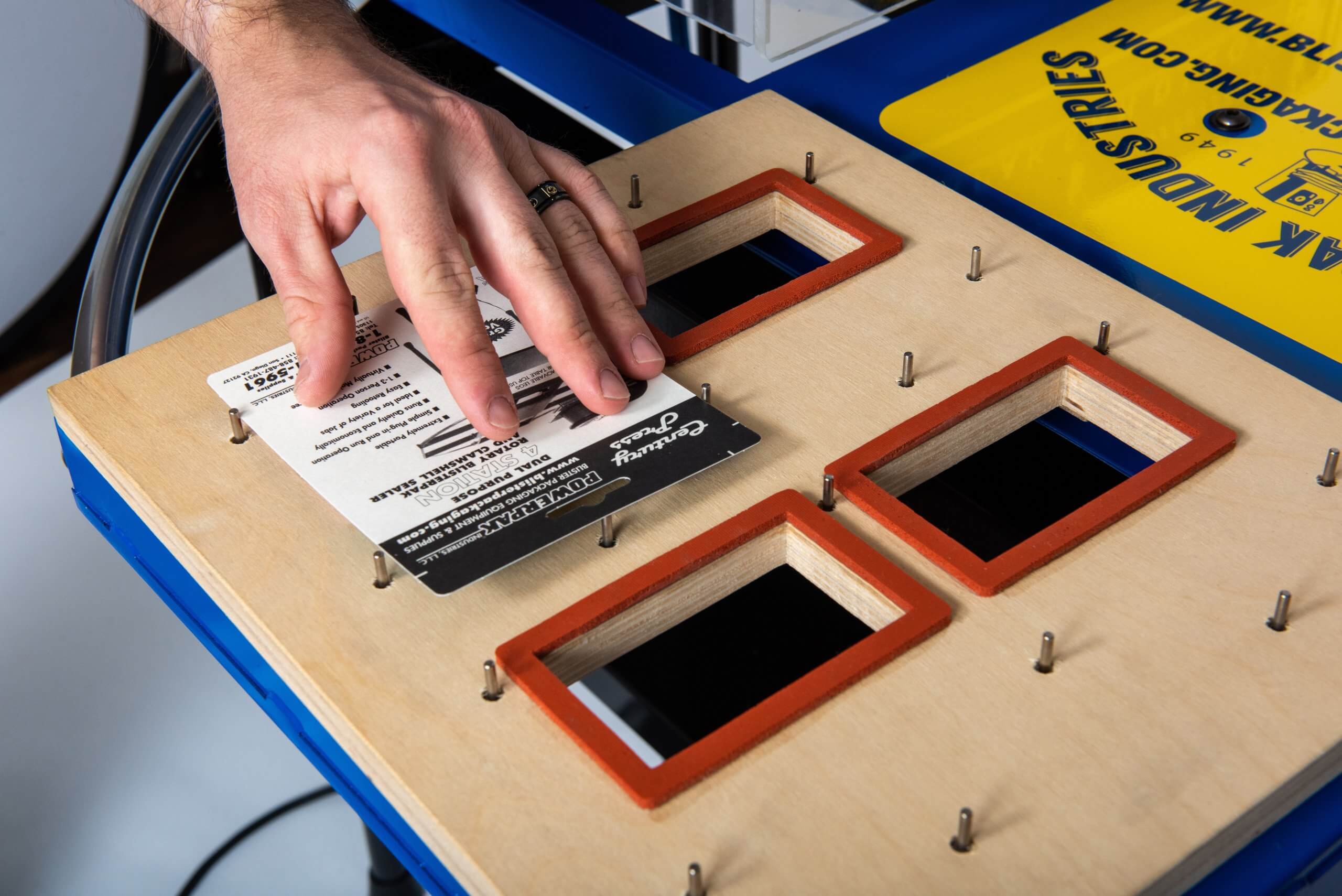

Learn more about POWERPAK Industries, LLC’s history in the blister packaging industry here.

Differentiating Blister Packaging

Distinct from other packaging methods, blister packaging has carved its niche by offering unique advantages in terms of product visibility, security, and convenience. By comparison, clamshell packaging, another type of thermoformed plastic packaging, has a hinged lid that encloses the product completely. Although clamshell packs provide excellent protection, blister packs surpass them in terms of cost-effectiveness due to their simpler design and the use of less material.

Let’s delve into the main types:

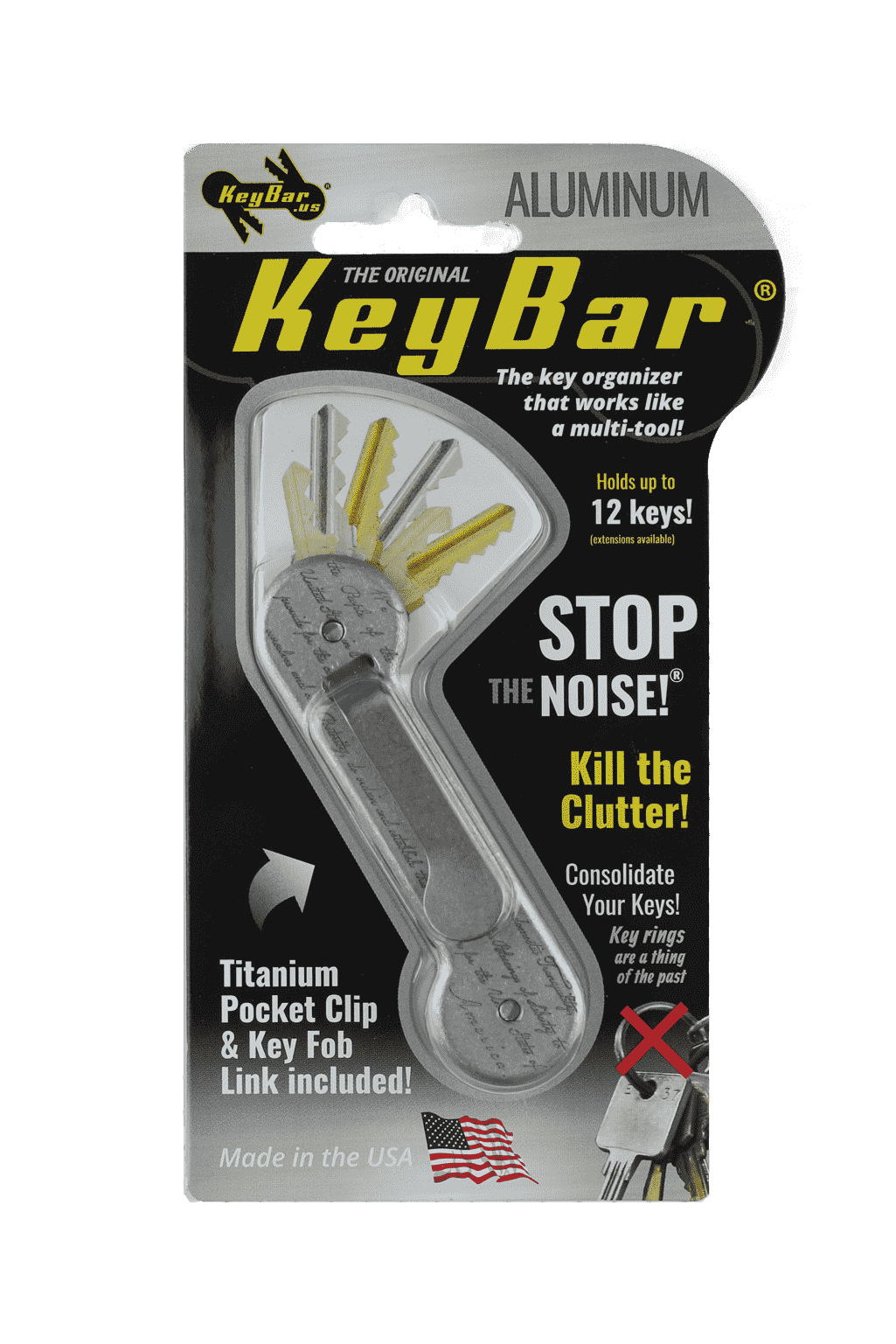

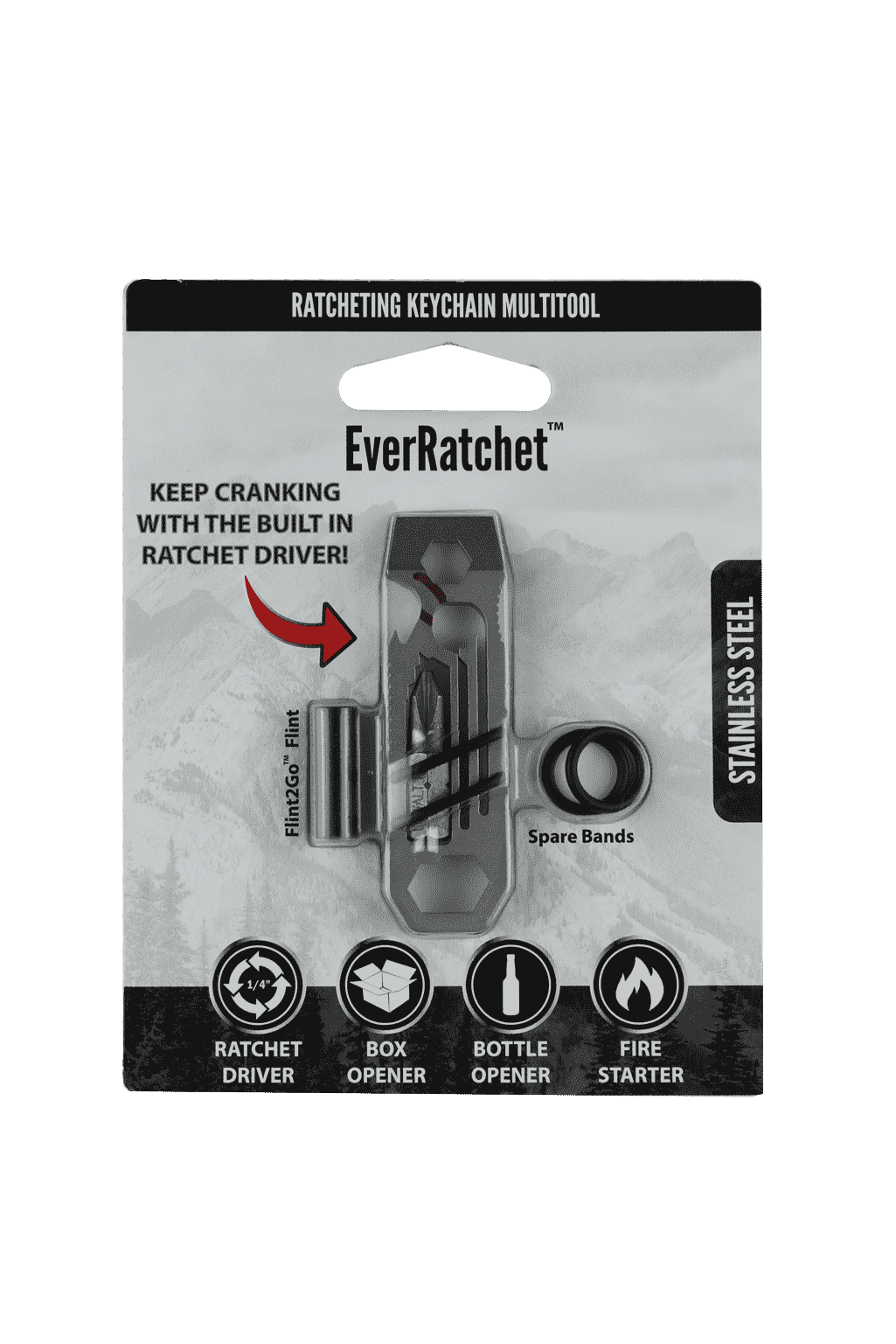

- Face Seal Blister: A widely adopted blister packaging method, the face seal blister features a custom-formed plastic blister that’s sealed to a card, offering exceptional product visibility. However, it doesn’t protect the edges of the card, and hence, is best suited for lighter, less fragile items such as stationery or small electronic components.

- Full Face Seal Blister: This is a variation of the face seal blister where the blister completely covers the card, providing added security and protection. Ideal for retail products like cosmetics or small hardware items, the full face seal blister ensures the packaged product stays secure and visually appealing.

- Trapped Blister: Trapped blister packaging involves sealing the plastic blister between two cards, delivering enhanced security. The high-quality aesthetic appeal and robust product protection make this type an excellent choice for pricier items, including premium fishing tackle or exclusive cosmetic products.

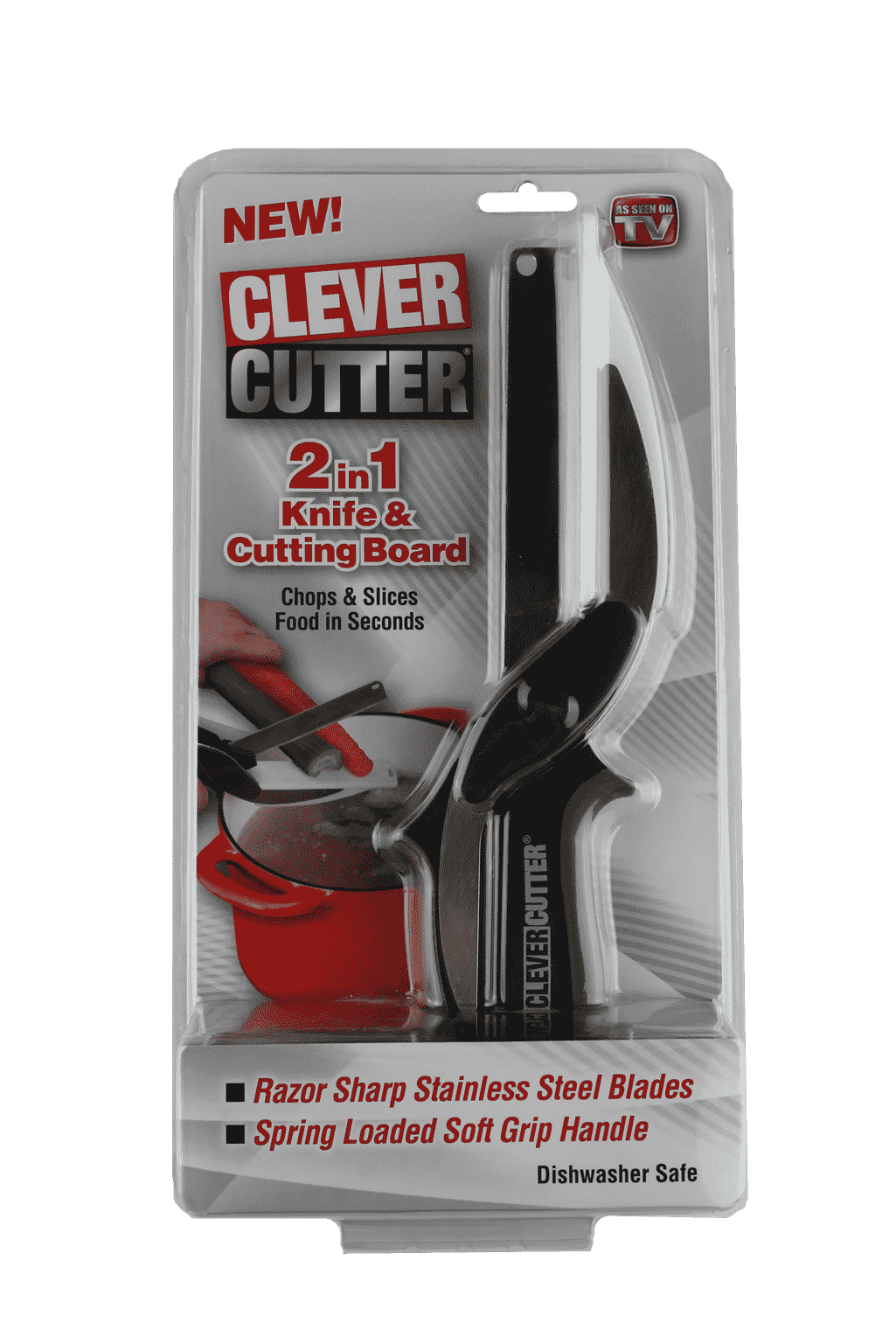

- Clamshell Packs: A stalwart in blister packaging, clamshell packs consist of a hinged blister that encloses the product entirely, providing optimal visibility and product protection. It’s often heat-sealed or stapled and is used widely for high-value or heavier items, such as golf products or high-end electronics.

- Slide Blister: Here, the blister pack slides onto a card that features a fold-over flap. Slide blisters offer strong product protection and are commonly used for heavier items, like tools or hunting products.

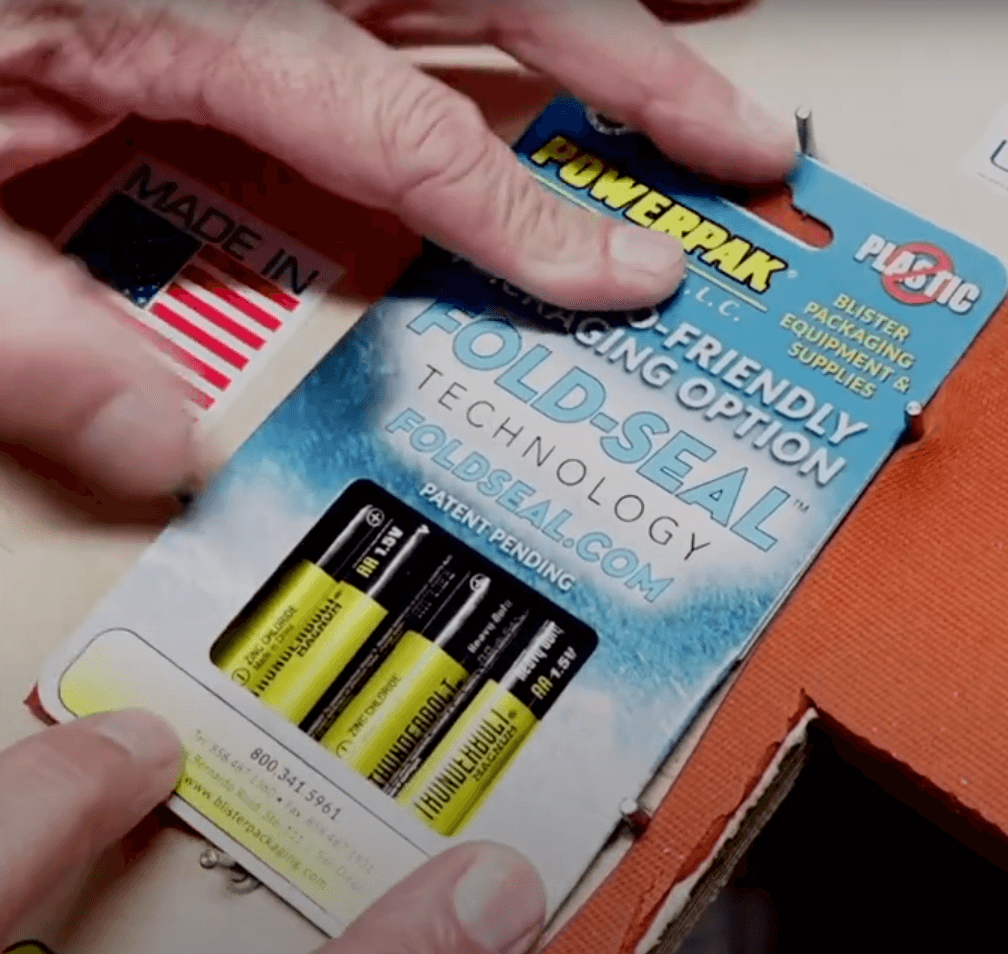

- Fold-Seal™ Packs: Fold-Seal™ Packs are exclusively designed to be completely recyclable, marking a significant step towards a greener future.

The type of blister packaging you choose hinges on the nature of the product, its weight, and your presentation preferences. As you navigate your options, consider the strengths and limitations of each type, and the impact your choice will have on the overall consumer experience.

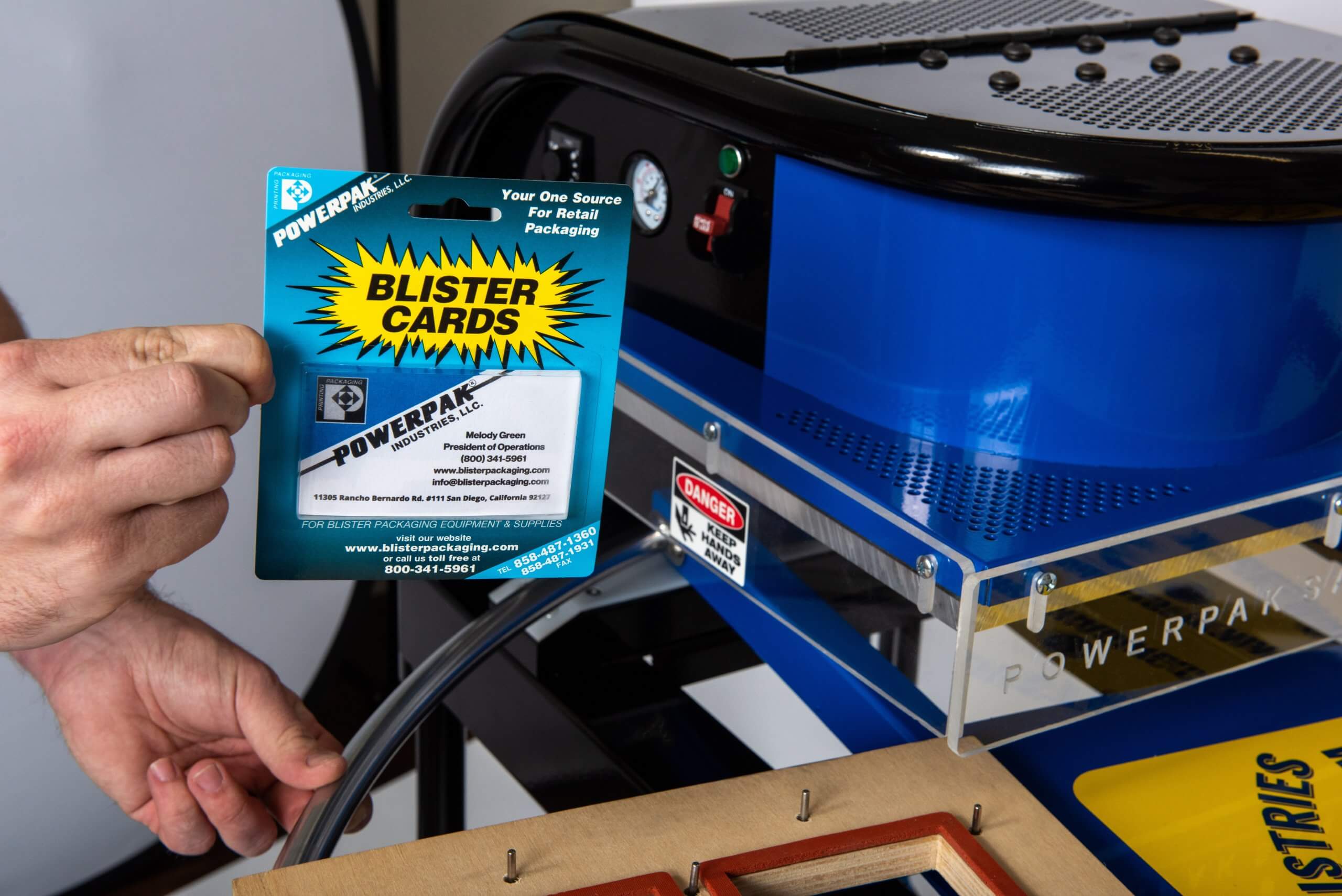

Blister packaging, with its myriad features, stands apart from other packaging methods. Whether it’s blister cards for pharmaceuticals, blister packs for toys, or even blister packaging machines used to streamline production, this method has proven to be both adaptable and practical for various industry needs.

Elements of Blister Packaging

Delving into the world of blister packaging, we encounter two key components: the blister itself and the backing. Firstly, the blister, a thermoformed plastic cavity, acts as a robust yet transparent shield. Its tailored shape not only encloses the product securely but also maintains its integrity during transportation and display. Its transparency, meanwhile, allows customers to view the product without opening the package, increasing buyer trust.

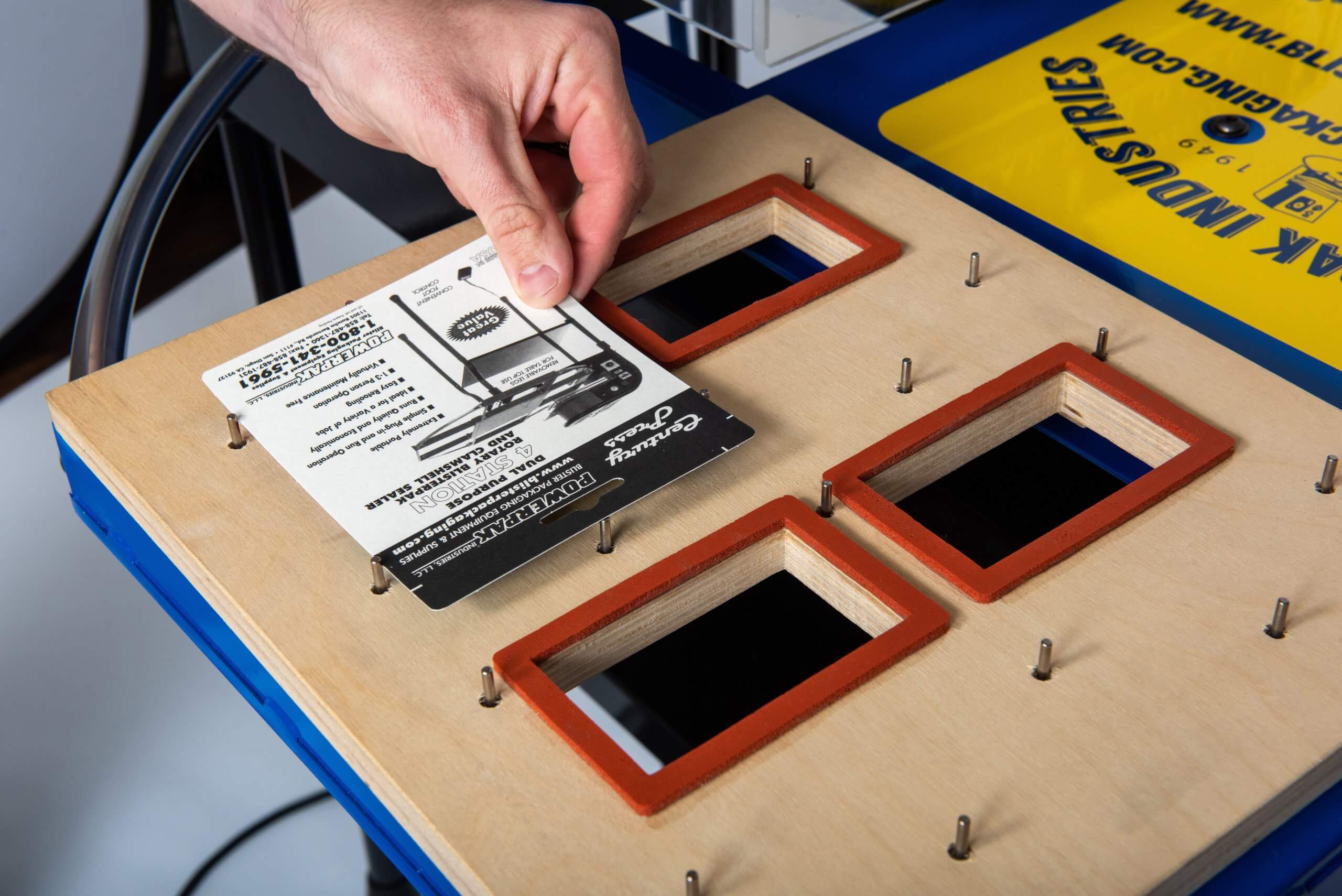

On the other hand, the backing, or blister card, forms the rear part of the packaging. It can be made from diverse materials, such as cardstock, foil, or plastic, depending on the product requirements and the degree of protection needed. Often, it’s sealed to the blister using heat or high-frequency ultrasonic energy through a blister packaging machine, creating a bond that only the end-user breaks. Cardstock backings also provide ample space for product information, branding, and instructions, adding to the overall retail appeal.

Here are the key components of retail blister packaging:

- The Blister: The ‘blister’ in blister packaging is the transparent, pre-formed plastic cavity that encloses the product. It’s usually made from thermoformed plastic, often PVC or PET, allowing customers to view the product directly. Besides visibility, it also provides a physical barrier, protecting the product from impact, tampering, and external contaminants.

- The Backing: The backing or blister card is what the blister is sealed onto. It can be constructed from various materials such as cardstock, foil, or plastic. The backing often carries essential product information, branding elements, and barcodes. In clamshell packs, which is a type of blister packaging, the backing can be another plastic shell, creating a hinged package that opens and closes like a clamshell.

- The Seal: The seal ensures the blister and backing stay secure. Sealing can be achieved using heat or high-frequency ultrasonic vibrations. Reliable blister packaging machines are pivotal for efficient sealing.

- Product: Last, but far from least, is the product itself. From toys and hardware to pharmaceuticals and electronics, blister packaging accommodates a broad array of products. The selection of the other elements often depends on the product’s characteristics.

Regardless of whether it’s a simple tool, an intricate fishing lure, a delicate cosmetic product, or even retail packaging supplies themselves, each item finds its custom-fit home in the world of blister packaging. Consequently, these two fundamental elements work harmoniously to deliver product protection, marketing benefits, and customer convenience, making blister packaging a versatile solution in the retail industry.

Benefits of Blister Packaging

Unraveling the benefits of blister packaging, one cannot overlook its cost-effectiveness, product protection, and marketing advantages. Firstly, the simplicity of its design translates into lower production costs. Be it a fishing lure or a sophisticated golf gadget, utilizing blister packaging machines allows for rapid, efficient packaging production, saving businesses both time and money. Furthermore, as a bonus, the minimized use of materials in blister packs reduces waste, promoting environmental consciousness.

Secondly, the secure sealing of blister cards and packs provides unparalleled product protection. This is crucial, not just for delicate cosmetics and pet products, but also for the robust hunting tools and duck calls. It shields the products from environmental conditions, handling, and tampering, thereby enhancing customer trust and product longevity.

Finally, the marketing advantages of blister packaging are extensive. The high product visibility through the clear blister allows customers to see the product before purchase. Additionally, the ample space on the blister cards allows for vibrant artwork and crucial product information, transforming the packaging itself into a marketing tool.

Here are the key benefits:

- Product Visibility: Blister packaging, with its transparent plastic cover, prominently displays the product, giving consumers a clear view of what they’re purchasing. This visual assurance helps to boost consumer confidence, consequently enhancing sales.

- Tamper-Evidence: A key advantage of blister packaging is its tamper-evident nature. Once a blister pack is opened, it’s immediately apparent, providing a clear indicator of product integrity. For industries such as pharmaceuticals and electronics, this feature is paramount in ensuring safety and quality.

- Cost-Effective: From a production perspective, blister packaging is often more cost-effective than other forms of packaging. The materials used are generally inexpensive, and the production process can be easily automated with the use of blister packaging machines, reducing labor costs.

- Versatility: Blister packaging caters to a wide range of products, from medication to small consumer electronics, making it a versatile packaging solution. Its ability to be customized in shape and size allows it to meet the diverse needs of different industries.

- Durability: Blister packs provide excellent protection from external elements, such as moisture, dust, and UV light. The hard plastic shell safeguards against physical damage, enhancing the product’s shelf life.

Therefore, the myriad benefits offered by blister packaging make it a go-to solution for diverse industries and an integral part of retail packaging supplies. With these advantages, it’s no wonder that its popularity continues to soar.

Drawbacks or Limitations of Blister Packaging

Though blister packaging offers an array of benefits, it’s essential to understand its limitations as well. First, some consumers express difficulty in opening blister packs, which is a vital consideration, especially for products aimed at seniors or children. This difficulty may extend to products like cosmetics or pet items that are frequently accessed, potentially leading to user frustration.

Moreover, although the lean design of blister packaging minimizes material use, the environmental impact of the materials used in blister packaging supplies should not be overlooked. The use of PVC in many blister packs has raised concerns due to its limited recyclability and potential environmental harm. As a result, manufacturers have been pushed to explore greener alternatives like PET and RPET.

Finally, the visibility that is such an asset to marketing can sometimes act as a disadvantage. High-value items are susceptible to theft due to this visibility, so additional security measures might be needed in retail settings.

Below are the key drawbacks:

- Difficult to Open: One common complaint about blister packaging is that it can be challenging to open. The plastic is tough and durable, which is excellent for protection but can lead to a frustrating experience for consumers. This can particularly be an issue for seniors or individuals with reduced hand strength.

- Limited Space for Branding: Compared to other forms of retail packaging, blister packaging provides less space for branding and information. While the transparent cover showcases the product well, it doesn’t leave much room for logos, descriptions, or other marketing material. Businesses often need to rely on the blister cards for this information, limiting the overall design scope.

- Environmental Concerns: The plastic used in blister packaging often contributes to environmental pollution. The recycling process is not straightforward, as the pack often contains different materials (like cardstock and plastic), which need to be separated before recycling.

- Not Suitable for All Products: While blister packs are versatile, they aren’t suitable for all product types. Bulky or irregular-shaped items may not fit well into standard blister packaging, necessitating custom solutions, which can increase costs.

These challenges, however, have encouraged innovation within the industry, resulting in safer, easier-to-open and more environmentally-friendly packaging solutions, including clamshell packs and more. Therefore, understanding these limitations is as vital as acknowledging the advantages when choosing the right packaging solution.

2. Types of Blister Packaging In Depth

Introduction Into The Different Types of Blister Packaging

Welcome to the dynamic and versatile world of retail packaging, where blister packaging enjoys broad acceptance due to its diverse applications. Let’s navigate the different types of blister packaging: face seal, full face seal, trapped blister, and clamshell, and delve into their key attributes.

Face Seal Packaging: This variant of blister packaging connects a blister to a blister card through a heat-sealing process. Due to its conservative use of materials, it’s an economical option. However, this type of blister pack only covers part of the card, leaving the rear exposed.

Full Face Seal Blister Packaging: True to its name, this type of blister pack seals the card entirely from edge to edge, thereby providing additional security. This packaging method is particularly suitable for lighter products, and it enhances the perceived value of the product.

Trapped Blister Packaging: Trapped blister packaging method places a product between two sealed cards surrounding the blister, perfect for heavier products. It also provides plenty of space for branding and vital product information, making it a popular choice.

Clamshell Packs: As hinged, one-piece packages, clamshell packs fold onto themselves, encapsulating a product much like a shell. These packs not only offer excellent product visibility but also provide a high degree of protection. Hence, they’re an ideal choice for fragile and high-value items.

Fold-Seal™ Packs: Fold-Seal™ Packs are exclusively designed to be completely recyclable, marking a significant step towards a greener future.

In essence, each packaging method carries its unique benefits. Therefore, gaining an understanding of their key features can aid in selecting the right blister packaging to meet your product’s needs.

Face Seal

Starting with face seal packaging, this format involves a blister card with a portion attached via a heat-sealing process. Known for its cost-effectiveness, it employs less material, leaving the card’s back visible. It’s ideal for lightweight products where the back exposure won’t compromise the product’s integrity.

In the diverse universe of blister packaging, face seal packaging stands out, acting as a frontrunner for affordability and efficiency. This format, remarkably simple yet brilliantly efficient, utilizes a blister card that’s partially attached through a heat-sealing process. The partial attachment does more than just cut down on blister packaging supplies – it leaves the back of the card visible, offering an additional display surface. Now, you might be wondering, “How does that translate into a win for my product?” Well, this visibility offers an opportunity to infuse your product with a distinctive edge in the crowded retail space. However, this is most effective for lightweight items, ensuring that the product’s integrity is not compromised by its exposure. With face seal blister packaging, you can effortlessly balance cost-effectiveness and consumer appeal, making it a smart choice in the complex realm of retail packaging.

Here’s a detailed look of examples:

- Toys: Face seal blister packaging is a go-to for many toy manufacturers. It provides a cost-effective solution that allows the product’s vibrant display, boosting its shelf appeal while maintaining security.

- Hardware Tools: Small hardware tools such as screws, nails, or hooks often find themselves packaged in face seal blister packs. The packaging’s transparent front enables customers to see the exact product, while the back card can carry detailed product specifications.

- Electronics Accessories: For smaller electronics accessories like USBs, earbuds, or charging cables, face seal blister packaging is an ideal choice. It protects the product from dust and damage while providing consumers with a clear view of the product.

- OTC Pharmaceuticals: Over-the-counter medications and health supplements often utilize face seal blister packaging for its efficiency and affordability. It ensures product integrity while providing ample space for necessary dosage and safety information.

Each application of face seal blister packaging highlights its multifaceted benefits: affordability, product visibility, and security. These advantages explain why industries ranging from toys to over-the-counter pharmaceuticals rely on this form of retail packaging.

Pro’s & Con’s of Face Seal Blister Packaging

In our blister packaging journey, face seal blister packaging emerges as an effective choice for a range of products. However, like any other packaging solution, it comes with its own set of pros and cons. Let’s explore these in detail:

Pros of Face Seal Blister Packaging:

- Cost-Efficiency: One of the most appealing advantages of face seal blister packaging is its cost-effectiveness. The manufacturing process requires less material compared to other packaging types, resulting in reduced costs.

- Product Visibility: Face seal blister packaging offers excellent visibility, allowing customers to view the product without opening the packaging. This feature enhances customer trust and boosts the chances of a sale.

- Versatility: Whether it’s toys, tools, or personal care products, face seal blister packaging serves a variety of industries. Its versatility extends its usage, making it a popular packaging choice for diverse products.

Cons of Face Seal Blister Packaging:

- Limited Security: While face seal blister packaging offers basic product protection, it may not be suitable for fragile or high-value items that require robust security.

- Not Eco-Friendly: Due to the use of plastic, face seal blister packaging is not the most environmentally friendly option. Brands conscious about their environmental footprint might need to explore alternative, greener packaging solutions.

- Opening Difficulty: Consumers often find it challenging to open blister packs. This minor inconvenience might affect the overall customer experience.

All in all, face seal blister packaging presents a mixed bag of pros and cons. While it’s cost-effective, offers great product visibility, and serves a variety of industries, its limited security, non-eco-friendly nature, and opening difficulties can’t be overlooked. However, for the right product, it can indeed be a practical retail packaging choice.

Full Face Seal

Taking a step further, the full face seal blister packaging provides a comprehensive seal from edge to edge. So, what does this mean for your product? Well, it offers heightened security and is well-suited for lighter products, creating an impression of higher value.

Full face seal blister packaging, often the next step in the blister packaging journey, brings a host of benefits to the table. Unlike its face seal counterpart, this design ensures a comprehensive seal, running from edge to edge. In essence, this packaging style acts as a safety blanket for your products, promising an added layer of security that consumers will appreciate. With a firm seal completely encasing the product, your customers will enjoy peace of mind knowing their purchase is safe from potential damage. And that’s not all. This packaging design isn’t just about functionality – it’s also a powerful marketing tool. By showcasing your product in a full face seal blister pack, you’re making a statement about your product’s value, even before consumers touch it. Despite being lightweight, this retail packaging technique can lend your product an air of prestige, transforming it from ordinary to extraordinary.

Let’s explore its common applications:

- Cosmetics: In the cosmetic world, full face seal blister packaging is frequently used for items like lipsticks, eyeliners, or nail polishes. This packaging not only lends an air of elegance but also ensures the product’s security and hygiene.

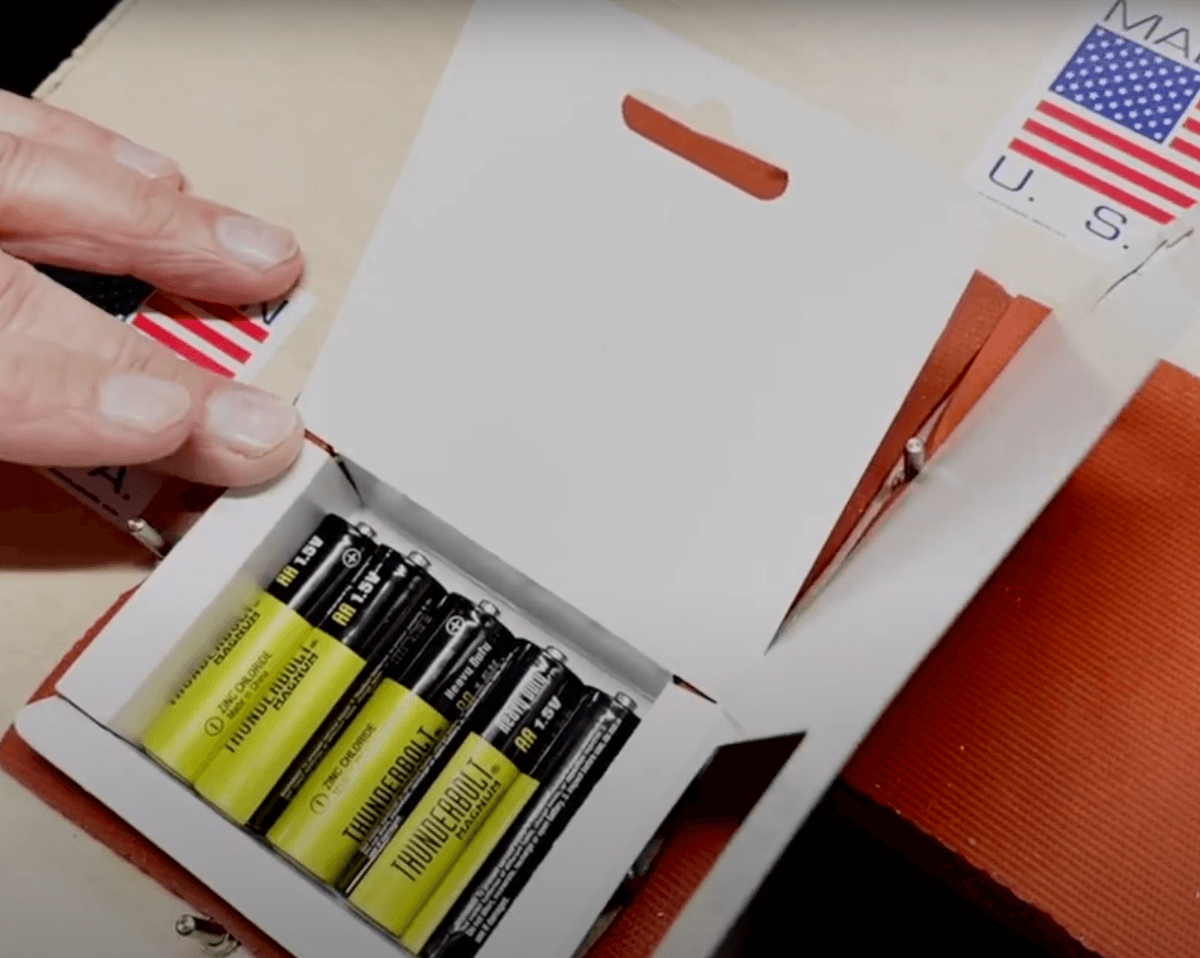

- Electronics: Small electronic devices, including memory cards, phone chargers, and batteries, are commonly packaged using full face seal blisters. The sturdy seal ensures the sensitive components are well-protected from external contaminants.

- Stationery: Full face seal blister packaging also finds extensive use in the stationery industry. From pens and pencils to erasers and sharpeners, this packaging type ensures these lightweight items are safely secured and well-displayed.

- Pharmaceuticals: Certain medications and health supplements also favor full face seal blister packaging. The complete sealing process ensures product integrity and tamper evidence while providing ample space for necessary dosage and safety information.

Indeed, full face seal blister packaging is a versatile packaging solution, satisfying the diverse needs of various industries. From cosmetics to pharmaceuticals, it’s a top pick for enhancing product security and showcasing product attributes effectively.

Pro’s & Con’s of Full Face Seal Blister Packaging

Pros of Full Face Seal Blister Packaging:

- Enhanced Branding: The full face seal blister packaging significantly amplifies branding opportunities. With ample space available on the blister card, companies can effectively utilize it to showcase brand identity and convey essential product information.

- Excellent Protection: Full face seal blister packaging offers impressive protection, thanks to its robust construction. Hence, it’s a preferred choice for securing valuable or fragile items against potential damages.

- Versatile Applications: From pharmaceuticals to electronics, the broad range of applications is another major benefit of full face seal blister packaging. It’s a versatile packaging solution that fits an array of industries’ requirements.

Cons of Full Face Seal Blister Packaging:

- Higher Costs: Due to the additional material used in the packaging, full face seal blister packs can be more expensive than other types of blister packaging.

- Environmental Concerns: Given that plastic is a significant component in this packaging, the environmental impact can be concerning. Thus, companies committed to sustainability might think twice before opting for full face seal blister packaging.

- Difficult to Open: As with other types of blister packs, full face seal blister packs can sometimes be challenging to open, which may cause some inconvenience to the customers.

To sum up, full face seal blister packaging offers superior protection, enhanced branding, and versatile applications, albeit at a higher cost, environmental concerns, and potential opening difficulties. Weighing these factors is essential in making an informed decision about the right retail packaging for your product.

Trapped Blister

The trapped blister packaging comes next, where a product finds itself comfortably sandwiched between two sealed cards. Given its robust construction, it’s an optimal pick for heavier products, offering ample space for vibrant branding and detailed product information.

The innovation in blister packaging doesn’t stop at full face seals. Trapped blister packaging is yet another excellent solution to consider. Picture a cozy sandwich with your product comfortably nestled between two securely sealed cards. Sounds secure, doesn’t it? Well, it certainly is! Designed with robust construction, this type of blister packaging is perfect for heavier products. Beyond its superior protective qualities, trapped blister packaging doubles as a blank canvas for showcasing your brand. Not only does it provide ample space for vibrant branding, but it also offers plenty of room for detailed product information. Therefore, while consumers can immediately identify your brand, they also have access to essential details, contributing to an informed purchase decision. Consequently, it’s safe to say that trapped blister packaging blends function with marketing finesse for a result that’s nothing short of impressive.

The common applications of trapped blister packaging, a favorite among manufacturers and retailers for its robust design and brilliant showcasing capabilities.

- Tools & Hardware: Trapped blister packaging shines when it comes to packing heavy tools and hardware items like drill bits, hammers, or screwdriver sets. The robust seal keeps the product securely in place while providing ample space for branding and detailed product information.

- Toys: Toy manufacturers often choose trapped blister packaging for action figures and small toy sets. The secure packaging protects the toys from damage and contamination while simultaneously showcasing the product to spark a child’s imagination.

- Electronics: For electronics like headphones, USB cables, or portable chargers, trapped blister packaging is an ideal choice. The firm seal offers robust protection, and the clear visibility allows customers to inspect the product without opening the packaging.

- Healthcare Products: From diagnostic kits to medical devices, healthcare products often use trapped blister packaging. The dual-card design safeguards the product and provides plenty of space for important instructions and safety warnings.

In summary, trapped blister packaging provides a harmonious blend of product protection and display benefits, making it a popular choice across various industries. From tools and toys to electronics and healthcare products, this packaging type continues to serve a diverse array of products with resounding success.

Pro’s & Con’s Of Trapped Blister Packaging

Next, let’s delve into the pros and cons of trapped blister packaging. Known for its sandwich-like structure where the product is encased between a layer of plastic and a blister card, trapped blister packaging can be an intriguing solution for your product packaging needs.

Pros of Trapped Blister Packaging:

- Superior Protection: Trapped blister packaging offers excellent product protection due to its double layer structure. Its unique design makes it an ideal option for delicate products susceptible to damage during transit.

- Visible Product Display: Even with its robust protection, trapped blister packaging allows clear visibility of the product, an aspect that can contribute to a product’s attractiveness in retail spaces.

- Increased Branding Space: With the product sandwiched between a card and plastic, there is ample space on both sides for branding, advertising, and necessary product information.

Cons of Trapped Blister Packaging:

- Higher Production Cost: Compared to its counterparts, trapped blister packaging can be relatively expensive due to the extra material and manufacturing processes involved.

- Environmental Impact: Just like other blister packs, the plastic component of trapped blister packaging poses environmental concerns. Companies with strong eco-friendly policies may need to consider this.

- Difficult to Open: A common issue with most blister packs, including trapped ones, is the challenge consumers often face when opening them.

While trapped blister packaging provides high-level protection, product visibility, and increased branding space, the consideration of a higher production cost, environmental impact, and potential difficulties in opening is paramount. Understanding these pros and cons can guide you to choose the best-suited blister packaging for your products.

Clamshell Packs

Characterized by its hinged, one-piece design, the clamshell pack folds onto itself, encasing a product in a ‘shell’. It not only offers an excellent visual showcase of your product but also provides stellar protection. This makes it a top contender for fragile and high-value items.

As we delve deeper into the world of blister packaging, we can’t skip mentioning the role of clamshell packs. If you’ve ever marveled at a product perfectly encapsulated in a clear ‘shell’, you’ve encountered a clamshell pack. Distinguished by its hinged, one-piece design, the clamshell pack cleverly folds onto itself, neatly enclosing your product within. But, its genius doesn’t stop there! This design goes beyond mere aesthetics. Indeed, while it superbly showcases your product, it concurrently offers stellar protection against the rigors of retail environments. For fragile and high-value items, a clamshell pack is a leading choice. It not only protects but also enhances your product’s visibility, creating an irresistible visual appeal. In essence, if protection and presentation are your top priorities, clamshell packs might be your go-to blister packaging solution.

The widespread uses of clamshell packaging, a packaging choice admired for its robust protection and visual appeal.

- Electronics: Clamshell packaging is commonly used for smaller electronics such as headphones, phone accessories, and memory cards. Its secure closure and clear view allow customers to inspect the product without compromising its integrity, adding a level of confidence during the purchase decision.

- Food Products: For fresh fruits, bakery items, or prepared salads, clamshell packaging is a popular choice. Its clear, secure, and resealable features maintain product freshness while providing consumers with a view of the food inside, enhancing their shopping experience.

- Personal Care Products: Ranging from high-end cosmetic items to everyday toothbrushes, clamshell packaging offers an excellent showcase for personal care products. The clear view ensures that customers can see exactly what they’re buying, while the robust design prevents any damage during transportation.

- Sporting Goods: Smaller sporting goods, such as golf balls or fishing equipment, often use clamshell packaging. This format offers excellent protection and visibility, allowing customers to assess the quality and details of the items before purchasing.

In a nutshell, clamshell packaging offers an unbeatable combination of robust protection, visual appeal, and practicality. Its versatility extends across industries, from electronics and food products to personal care items and sporting goods, enhancing both the retailer’s product presentation and the customer’s shopping experience. It’s easy to see why it continues to be a popular choice in retail packaging.

Pro’s & Con’s Of Clamshell Blister Packaging

To continue our exploration, let’s consider the pros and cons of clamshell blister packaging, a unique and versatile solution in the world of blister packaging. This packaging type, as its name suggests, resembles a clamshell with its hinged design that opens and closes like the shell of a clam.

Pros of Clamshell Blister Packaging:

- Robust Protection: The hardy plastic shell provides superior protection against physical impacts, making it ideal for fragile items.

- Transparent Display: The transparent nature of clamshell packs allows customers to view the product from all angles, enhancing the in-store experience.

- Tamper-Evident: Once sealed, clamshell packaging is notoriously hard to open, making it an excellent deterrent against theft and ensuring product integrity.

Cons of Clamshell Blister Packaging:

- Difficult to Open: Ironically, the same feature that provides security can be a significant drawback. Consumers often find clamshell packs challenging to open, leading to the phenomenon known as “wrap rage.”

- Costlier Option: The manufacturing process and the amount of material used in clamshell packaging can make it more expensive than other blister packaging options.

- Environmental Impact: Like all blister packs, clamshell packaging has an environmental impact due to its plastic content, which is a crucial consideration for eco-conscious companies.

While the clamshell blister packaging offers robust protection, a transparent display of products, and tamper-evidence, you need to consider the drawbacks of potentially frustrating the end-users, slightly higher costs, and environmental concerns. Your product’s unique needs and target audience preferences should guide your choice in the vast landscape of blister packaging options.

Fold-Seal™ Packs

Introducing a groundbreaking solution within the packaging industry – Fold-Seal™ Packs. As the world edges towards sustainable practices, it’s crucial for industries to align. First, Fold-Seal™ Packs represent a revolutionary leap in this direction by reducing the use of plastic in packaging, aligning perfectly with eco-conscious business practices. These packs, unlike traditional blister packs, leverage state-of-the-art design and materials to secure products efficiently without compromising environmental responsibility.

In addition, Fold-Seal™ Packs are not only a greener option, but they also offer robust protection for your items. Through a unique blend of flexibility and strength, these packs safeguard your products during transit, minimizing damage and ensuring customer satisfaction.

Moreover, adopting Fold-Seal™ Packs doesn’t require a complete overhaul of your existing packaging equipment. Many blister packaging machines can adapt to these packs with minimal modification, allowing a smooth transition for businesses seeking a more sustainable packaging method. As such, if you’re on a mission to reduce your carbon footprint while maintaining high packaging standards, Fold-Seal™ Packs offer the perfect blend of efficiency and responsibility.

So, are you ready to take the next step towards sustainability? Embrace the future with Fold-Seal™ Packs, and join countless other businesses revolutionizing their retail packaging strategies. There’s no better time than now to invest in the future – a future that values both our planet and profit.

Common uses of old-Seal™ Packs

Let’s delve into some of the top applications where Fold-Seal™ Packs can make a significant impact:

- Pharmaceutical Industry: In an industry where safety and security are paramount, Fold-Seal™ Packs offer a reliable solution. With its robust and secure design, these packs ensure the integrity of the product, preventing tampering and contamination. As a result, they become a top choice for packaging tablets, capsules, and other medical supplies.

- Electronics: Small electronic components, especially those susceptible to static electricity, can benefit from Fold-Seal™ Packs. Thanks to their protective properties, these packs shield the components from damage and degradation, ensuring they reach the end-user in pristine condition.

- Food and Beverage: Fold-Seal™ Packs can offer a secure packaging option for various food items. The packs ensure the product’s freshness, contributing to the preservation of flavor and extending the product’s shelf life.

- Cosmetics: Products like lipsticks, eyeliners, and compact powders are often delicate and require superior packaging. Fold-Seal™ Packs, being sturdy and protective, make an excellent packaging choice in the cosmetics industry.

- Toy Industry: Small toy parts, collectibles, and other components can be securely packaged using Fold-Seal™ Packs. The transparent design of these packs allows potential buyers to see the product clearly, boosting customer engagement and interest.

So, as you can see, Fold-Seal™ Packs are incredibly versatile, finding application across numerous industries. Whether you’re in the pharmaceutical business or retailing cosmetics, these packs offer an efficient, secure, and environmentally friendly blister packaging solution.

Pro’s & Cons of Fold-Seal™ Packs

Pros:

- Environmental Friendliness: A prominent advantage of Fold-Seal™ Packs is their environmentally friendly nature. Given that they are made without the use of plastic, these packs significantly reduce environmental pollution. Thus, they offer an excellent alternative to traditional blister packs for companies aiming to minimize their carbon footprint.

- Product Protection: Fold-Seal™ Packs provide superior product protection. They are designed to shield the product from contamination, tampering, and damage, ensuring product integrity from production to the end user.

- Versatility: Fold-Seal™ Packs are incredibly versatile and can be used across various industries, including pharmaceuticals, electronics, food and beverage, cosmetics, and toy industries.

Cons:

- Cost: While Fold-Seal™ Packs offer numerous advantages, they might come with a higher price tag compared to traditional packaging materials. Therefore, cost could be a potential downside, particularly for small businesses with tight budgets.

- Specialized Sealing Machines: Fold-Seal™ Packs might require the use of specialized blister packaging machines for sealing, which could result in additional initial investment costs.

- Packaging Speed: The sealing process with Fold-Seal™ Packs might be slower than with plastic alternatives, potentially impacting packaging speed and efficiency.

In conclusion, while Fold-Seal™ Packs offer significant environmental and protection benefits, it’s essential to balance these advantages against the potential higher costs and possible slowdown in packaging speed. Therefore, businesses need to make an informed decision based on their specific requirements and constraints when considering the adoption of Fold-Seal™ Packs as their primary packaging solution.

Environmental Impact of Each Blister Packaging Type

In the face of escalating environmental concerns, the sustainability of packaging methods is indeed crucial. Let’s delve into the environmental impact of each type of blister packaging, focusing on recyclability, the carbon footprint of production, and green initiatives for improvement.

Face Seal Blister Packaging: Being primarily a paper card and plastic combination, the face seal variant does pose some challenges in terms of recycling, particularly the separation of these materials. However, many manufacturers are exploring the use of easily separable or fully recyclable materials to minimize environmental impact. Despite these hurdles, face seal packaging typically has a smaller carbon footprint due to the lesser amount of plastic used compared to other types.

Full Face Seal and Trapped Blister Packaging: The recyclability issues are similar to face seal packaging. On the positive side, some companies are now employing blister packaging supplies made from recycled materials, thereby reducing the carbon footprint. Additionally, many manufacturers are researching more environmentally-friendly adhesives for sealing the packaging.

Clamshell Packaging: Clamshell packs, comprised entirely of plastic, have the most significant environmental impact due to the difficulty in recycling mixed plastic materials. While initiatives are in progress to design clamshell packs that can be more easily broken down for recycling, the larger volume of plastic contributes to a higher carbon footprint. However, strides are being made in the use of biodegradable and compostable plastics.

Fold-Seal™ Packs: Fold-Seal™ Packs present a revolutionary alternative to traditional packaging methods, offering an environmentally friendly solution without the use of plastic. These innovative packs demonstrate that sustainability and efficiency can go hand-in-hand, reducing our ecological footprint while meeting our packaging needs with excellence.

In conclusion, while each type of blister packaging has its environmental considerations, there are ongoing industry initiatives to innovate and improve their sustainability profiles. As we look to the future, an increased emphasis on using recycled materials, finding greener alternatives, and enhancing recyclability will play pivotal roles in shaping the environmental impact of blister packaging.

Choosing the Right Type of Blister Packaging

Selecting the ideal type of blister packaging for your business may seem challenging, but by focusing on a few key aspects, it becomes less daunting. First and foremost, consider the nature of your product. For smaller, lighter items like jewelry or consumer electronics, face seal or full face seal blister packs might be ideal due to their economical use of materials. Heavier items may benefit from the robust protection offered by trapped blister or clamshell packaging.

Moving on, the product’s size plays a critical role. Large retail items often demand clamshell packs due to their spacious design and superior visibility, enhancing the product’s marketing appeal. On the other hand, small products benefit from the compact size of face seal blister packs. Furthermore, consider your budget. Face seal and full face seal options are generally more cost-effective, while clamshell packs might entail higher costs due to the greater amount of material used.

Notably, another point of consideration is your brand’s stance on environmental responsibility. As sustainability becomes a key differentiator in today’s market, the environmental impact of your packaging solution could significantly influence customer perception. Blister packaging made from recycled or easily recyclable materials can boost your green credentials.

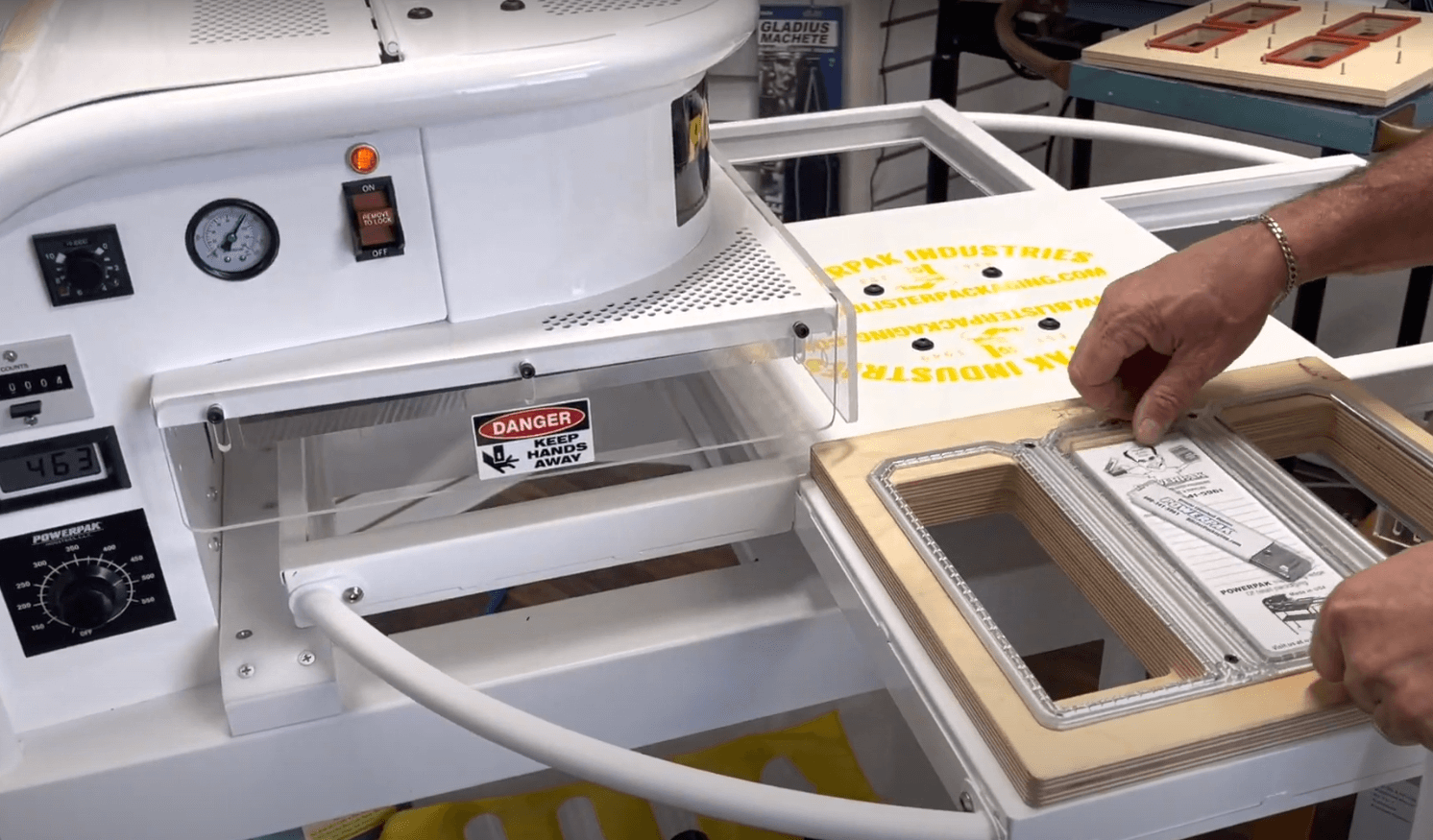

Lastly, remember that the right blister packaging machine can enhance productivity and maintain quality control. A clamshell sealing machine, for instance, can expedite the process for clamshell packs.

In conclusion, when choosing the most suitable blister packaging, weigh these factors against each other. A clear understanding of your product’s attributes, your budget, marketing considerations, and sustainability goals will guide you towards the most effective and efficient blister packaging solution.

3. Materials Used in Blister Packaging

Delving into the world of blister packaging, you’ll find a variety of materials skillfully utilized to ensure product safety and boost visual appeal.

- PVC (Polyvinyl Chloride): Undeniably, PVC is a champion in the blister packaging arena. Thanks to its adaptability and low cost, this material is a popular choice among manufacturers. With a knack for flexibility, PVC effortlessly conforms to the product shape, providing secure packaging while also offering clear visibility for consumers. However, it’s important to keep in mind that PVC isn’t a friend to the environment due to its difficult recycling process.

- PET (Polyethylene Terephthalate): For those seeking an eco-friendly alternative, PET stands tall. Not only is it recyclable, but it’s also resilient, offering superior protection against external factors. Therefore, PET is often seen hugging electronics, toys, and other fragile goods. On the flip side, PET’s production process is more energy-intensive compared to PVC.

- PP (Polypropylene): PP’s unique selling point is its high melting point. Consequently, it’s an excellent pick for blister packs that need to withstand heat during the sealing process or while housing products prone to heat. However, despite PP being recyclable, its widespread use in retail packaging is hampered due to its lower clarity compared to PVC or PET.

- PE (Polyethylene): PE is primarily used for its excellent resistance to chemicals. Hence, it is often utilized in pharmaceutical blister packs, safeguarding medicines from potential damage. While PE is an economical choice and recyclable, it offers lower rigidity than other materials.

Besides the plastic materials mentioned, other components like cardboard, paper, ink, and adhesives play a crucial role in blister packaging. Let’s delve deeper into these:

- Cardboard/Paper: An indispensable part of blister packs, cardboard or paper serves as the backing onto which the plastic blister is attached. This offers a canvas for marketing messages, brand logos, product information, and instructions. In many blister packaging types like face seal and trapped blister packs, cardboard is used, making these packages partially recyclable and more environmentally friendly.

- Inks: Used for printing on the cardboard or paper backing, inks bring life to the packaging. The right choice of ink can influence the product’s visual appeal and convey brand identity. Besides aesthetic considerations, some inks are resistant to UV light, water, and chemicals, preserving the integrity of printed information.

- Adhesives: Adhesives are essential for sealing the blister to the backing card in face seal and trapped blister packaging. The choice of adhesive can impact the package’s tamper-resistance and ability to endure various temperatures and pressures.

- Aluminum Foils: Commonly used in pharmaceutical blister packaging, aluminum foils help form the push-through backing of such packs. They provide excellent barrier properties, protecting sensitive medicines from moisture, light, and oxygen.

The interplay of these materials, chosen based on product requirements, cost, and environmental considerations, ultimately shapes the performance and appeal of blister packaging.

In conclusion, when selecting blister packaging materials, it’s crucial to understand the strengths and limitations of each. Choose wisely, keeping in mind your product needs, budget, and commitment to the environment. Remember, the right blister packaging can be the difference between a product reaching a customer in perfect condition or damaged, impacting your brand reputation.

Comparison of Each Material

Unpacking the diverse range of materials used in blister packaging, we must consider their unique attributes and respective applications. First up is PVC, the most commonly used plastic in blister packaging. It’s a popular choice due to its durability, excellent barrier properties, and low cost. On the flip side, however, PVC isn’t as environmentally friendly as other options.

Next, we have PET, another frequently used plastic in blister packaging. PET boasts excellent clarity and high impact resistance, lending itself well to retail display purposes. However, compared to PVC, it is more costly. So, while PET outshines PVC in environmental compatibility, cost factors could come into play.

Thirdly, we look at PP, known for its heat resistance. Ideal for applications requiring autoclaving or hot filling, PP’s major downside is its hazy appearance, which could obscure product visibility.

PE, on the other hand, finds its niche in applications demanding flexibility and high tear strength, although it falls short in terms of transparency and rigidity.

Then, we have Cardboard. Offering a canvas for engaging visuals and product information, cardboard enhances the packaging’s aesthetic appeal and provides additional rigidity. However, it’s not suitable for moisture-prone environments.

Inks and Adhesives play a crucial role in the packaging’s aesthetic appeal and integrity, respectively. Choosing the right ones can make a world of difference in terms of visual impact and product protection.

Finally, Aluminum Foil is the go-to choice for pharmaceutical blister packaging due to its excellent barrier properties. While it provides optimal protection, it contributes to higher packaging costs.

Ultimately, the selection of materials for blister packaging hinges on a myriad of factors: product requirements, cost, and environmental considerations. As such, balancing these elements is key to optimized blister packaging solutions.

Price & Cost Implications of Each Material

When it comes to the cost implications of materials used in blister packaging, a comprehensive understanding of each is vital. For instance, PVC, owing to its wide availability and relatively simple production process, often represents a cost-effective choice. Nevertheless, its environmental drawbacks might lead to long-term costs, like potential disposal fees or consumer backlash.

Contrastingly, PET typically has a higher upfront cost than PVC, attributed to its higher production cost. Yet, it scores better on sustainability, possibly reducing future costs related to environmental compliance. Not to mention, its high clarity can boost product appeal, potentially leading to higher sales.

Meanwhile, PP is a somewhat pricier option due to its heat-resistant properties. However, the cost could be justified if you need packaging to withstand high temperatures during sterilization.

PE often competes with PVC in terms of cost-effectiveness, but like PVC, its limited clarity and rigidity might affect product presentation and, by extension, sales.

The usage of Cardboard, Inks, and Adhesives can increase costs due to the complexity they add to the manufacturing process. Yet, their aesthetic contribution could lead to enhanced customer appeal and better product differentiation, possibly boosting revenue in the long run.

Finally, Aluminum Foil stands as the most expensive material due to its excellent barrier properties, commonly reserved for pharmaceutical applications where product protection is paramount.

In summary, the choice of material in blister packaging isn’t solely a matter of upfront costs. Factors like product requirements, sustainability, and potential impact on sales can significantly affect the overall cost implication. Hence, a balanced approach to material selection can lead to efficient, cost-effective blister packaging.

4. Designing Blister Packages

Fundamentals of Blister Packaging Design

Embracing the art of blister packaging design is a game-changing decision for any product-centric enterprise. Firstly, the primary purpose of this design is not only to safeguard your product, but also to enhance its appeal to potential customers. To attain that, visibility is a key element. An optimal blister packaging design should exhibit your product prominently. It should captivate customers, persuading them to choose your product amidst a sea of alternatives.

Aesthetics, too, hold a fundamental role in the design process. While the functional aspects of the packaging provide protection, the aesthetic attributes significantly contribute to your branding and marketing. It’s essential to merge your brand’s visual identity into the packaging design seamlessly. This includes your brand colors, fonts, logos, and any other relevant design elements. Remember, a well-designed blister packaging can act as a silent salesperson, drawing customers in and influencing purchasing decisions.

Choosing the right retail packaging supplies and using efficient blister packaging machines also play a part in delivering an impeccable design. By ensuring the design and production processes are meticulously carried out, you set the stage for a superior unboxing experience, which ultimately helps in forging a stronger bond with your customers. So, invest in blister packaging design – it’s your silent brand ambassador, ensuring your product stands out in the bustling retail market.

Breakdown of the core principles:

- Purpose: At the heart of blister packaging design is its primary purpose – to protect and display the product. A well-designed blister pack secures the product during transit, prevents tampering, and provides an effective barrier against moisture, dust, and other environmental factors.

- Visibility: With blister packaging, you’re essentially giving your customers a sneak peek into what they are purchasing. The design should maximize product visibility, allowing consumers to view the product from different angles. A clear, high-quality plastic blister enhances visibility and instills buyer confidence.

- Aesthetics: In the competitive retail landscape, the design aesthetics of blister packaging can make a significant impact on product sales. Elements like color, shape, and graphics play a vital role in capturing customer attention. Consequently, the blister card should be appealing, with clear branding and concise product information.

- Ease of Use: Consumers appreciate packaging that’s easy to open but also secure. It’s crucial to strike a balance between these two aspects. Clamshell packaging, for example, offers a robust, resealable option, while a simple face seal blister pack might be ideal for more cost-sensitive items.

- Environmental Considerations: As consumers become more environmentally conscious, choosing recyclable materials like PET for your blister packaging can improve your brand image. In addition, considering the packaging’s end-of-life in the design phase can contribute significantly to your company’s sustainability efforts.

Material Selection

In the realm of blister packaging design, the selection of the right material is as crucial as the creative aspect itself. Firstly, PVC, a material that’s widely used in blister packaging, is prized for its transparency and robustness. This allows for clear visibility of the product while offering reliable protection, leading to a design that’s both visually enticing and sturdy.

Furthermore, PET is another common choice, particularly lauded for its recyclability, a trait that’s crucial in today’s eco-conscious world. When PET is used in the design, it sends a message about your brand’s commitment to sustainability, subtly enhancing your brand image in the eyes of environmentally conscious consumers.

Additionally, don’t forget that each material behaves differently in blister packaging machines. As such, understanding the characteristics of each can aid in creating a seamless production process, ensuring that your design doesn’t just look good, but also performs well in terms of manufacturing efficiency.

When it comes to blister packaging supplies, balancing aesthetics, functionality, and sustainability is key. The material you choose greatly influences these factors and can create a lasting impression on your consumers. So, take your time to explore your options and select the right materials for your blister packaging design. It’s a crucial step towards achieving retail success.

Consideration of Product Type and Size

A critical consideration in the world of blister packaging is the nature and dimensions of the product being packaged. First, the type of product significantly impacts the choice of design. For instance, high-value items might call for clamshell packs, providing enhanced visibility and robust protection. Additionally, the size of the product isn’t just a measurement; it’s a design determinant that affects the scale of the packaging. A well-designed blister pack has the power to enhance product display and grab consumer attention.

Consider a small-sized product like an electronic accessory. Designing blister packaging for such items requires precision, as it should ensure the product’s visibility without being overwhelmingly large. On the other hand, larger items might require full face seal blister packs to provide ample coverage and protection.

Next, let’s think about blister packaging machines. Ensuring that your packaging design can be efficiently produced by your chosen machinery is essential. The last thing you want is a design that looks good on paper but causes logistical nightmares in production.

In conclusion, considering the type and size of your product plays a crucial role in determining the most effective blister packaging design. It’s not just about looks—it’s about function, efficiency, and creating a memorable unboxing experience for your consumers.

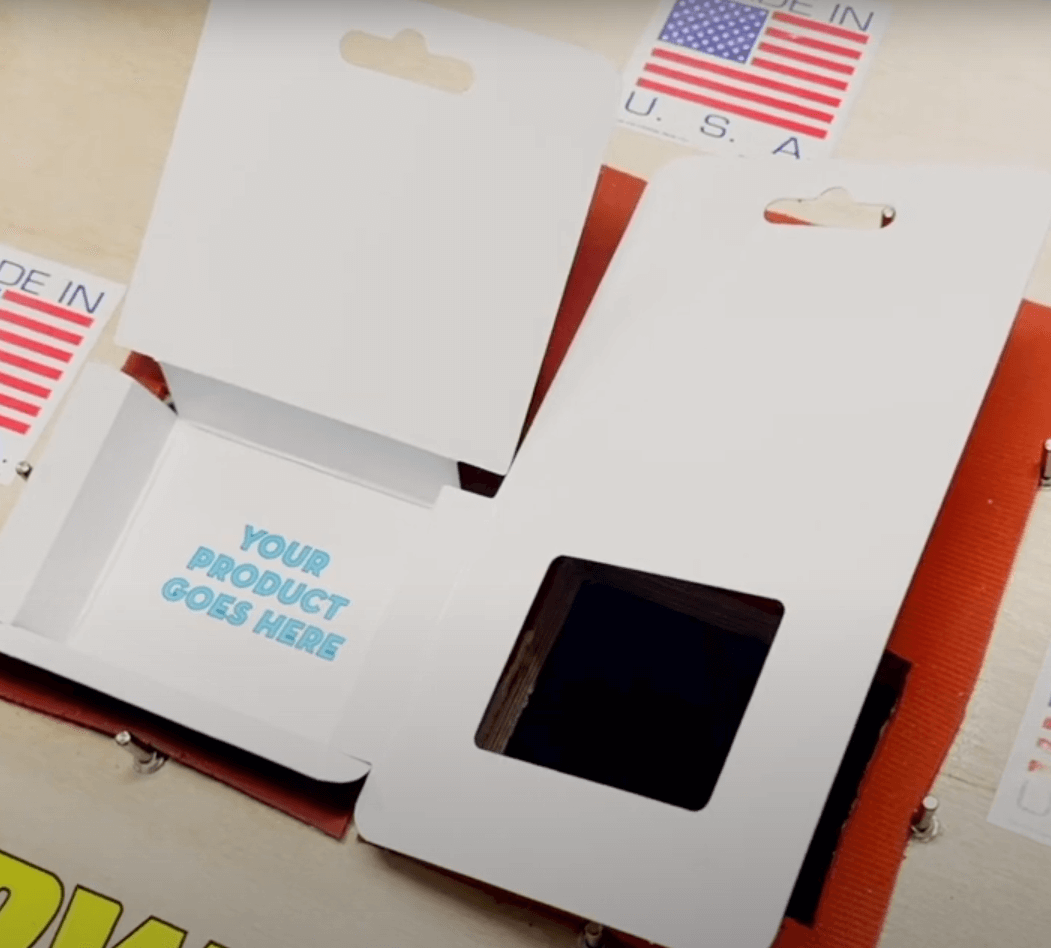

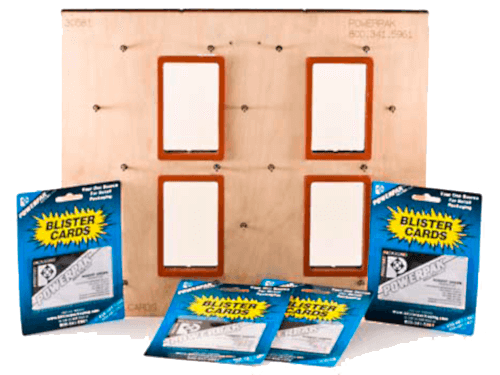

Creating the Blister and Backing

Crafting the ideal blister packaging requires meticulous design of both the blister and the backing. Let’s delve into the fascinating process that brings your product packaging to life. First, the creation of the blister, the clear plastic part that houses your product, requires keen attention to details. The blister’s size and shape should be tailored to the product, enhancing its visibility while providing optimal protection. Moreover, features like hinged lids or snap closures can be added for products that require secure resealing.

Moving onto the backing, also known as blister cards, it’s not just a support structure, but a canvas for your brand’s story. Beyond the shape and size, which need to match the blister perfectly, one should factor in the material’s rigidity and ability to endure the heat from the blister packaging machines. Furthermore, the design on the backing is an opportunity for branding and communicating crucial product information. Using vibrant colors, compelling imagery, and easy-to-read fonts can set your product apart in a crowded retail environment.

Ultimately, the design of blister packs should be a harmonious marriage of functionality and aesthetics. It’s a delicate balance that, when struck perfectly, creates a winning retail packaging strategy.

The process of designing the essential components of blister packaging, namely the blister and the backing, is a fascinating journey. Allow me to guide you through these crucial steps:

- Define the blister size and shape: The initial step in blister packaging design involves defining the size and shape of the blister. This clear plastic part should be precisely tailored to the product, not only to enhance visibility but also to ensure optimal protection.

- Consider additional features for the blister: Depending on the product, your blister might need specific features. For instance, hinged lids or snap closures can be incorporated for products that require secure resealing after opening.

- Choose the right materials for the backing: The backing, often known as the blister card, plays an essential role in blister packs. It should be rigid enough to provide support and withstand the heat from the blister packaging machines during the sealing process.

- Define the size and shape of the backing: Just like the blister, the size and shape of the backing need to be meticulously defined. It should perfectly match the blister, providing a seamless fit.

- Design the backing: The design phase of the backing can be seen as an exciting opportunity for branding. A well-designed backing using compelling imagery, vibrant colors, and legible fonts can make your product stand out on retail shelves.

By following these steps, one can design a blister package that strikes a perfect balance between functionality and aesthetics. The ultimate goal is to ensure your retail packaging is not just a container, but also a silent salesperson on the shelf, showcasing the product and conveying your brand’s message.

Branding and Graphic Design

In the bustling arena of retail marketing, it’s no longer enough for a product to be merely useful or high quality. Aesthetics, branding, and presentation play a paramount role in influencing consumer choices. When it comes to blister packaging, the integration of branding elements can significantly enhance the product’s market appeal.

Firstly, consider the color scheme. Much like a company’s logo, colors are an essential part of a brand’s identity. They evoke specific emotions and associations that influence buying decisions. The colors used in your blister packaging should, therefore, align with your brand’s color palette, creating a cohesive visual experience that resonates with your customers.

Next, the strategic placement of your logo is crucial. Often, the logo is placed on the blister card, which acts as a backdrop to the product enclosed in the clear plastic blister. Make sure your logo is visible and prominent, effectively serving as a silent salesperson on the retail shelf.

Then, let’s not forget the product information and other design elements. While you want your blister packaging to be aesthetically pleasing, it also needs to be informative. Include essential details like product features, usage instructions, and safety precautions. Use compelling graphics and typography that align with your brand’s style guide.

Lastly, consider adding unique design elements that differentiate your product from competitors. This could be an unusual shape for your clamshell pack or a distinctive design on the blister card. These elements can serve as a form of visual storytelling, connecting consumers to your brand narrative.

In essence, an effective blister packaging design should be more than a protective container. It should be a dynamic canvas that encapsulates your brand’s identity, stimulates interest, and ultimately, persuades consumers to choose your product amidst a sea of options.

Here are some vital points to consider:

- Color Scheme: The role of colors in retail packaging can’t be overstated. A brand’s color scheme is often the first thing that grabs the consumer’s attention, triggering emotional responses that drive purchasing behavior. Therefore, your blister packs should incorporate your brand’s color palette, ensuring instant recognition and evoking the desired feelings among consumers.

- Logo Placement: Your logo is the visual representation of your brand. Therefore, strategically positioning it on your blister packaging is essential. Typically, the logo finds its home on the blister card, offering a bold and clear display. It should be prominent and visible even from a distance, serving as a silent ambassador for your brand on the retail shelf.

- Product Information and Design Elements: While aesthetics matter, it’s equally crucial to inform potential buyers about the product. The blister card provides an excellent platform to communicate product features, usage instructions, and other key information. Choose graphics and typography that align with your brand style, making sure that the packaging design is informative as well as visually appealing.

- Unique Design Elements: In the competitive retail landscape, standing out is paramount. Incorporate unique design elements into your blister packaging that help differentiate your product from the competition. This could be an innovative shape for your clamshell packs or an eye-catching design on the blister card. Such elements not only attract attention but can also communicate your brand’s story.

Remember, blister packaging is more than a protective shield; it’s a dynamic canvas that encapsulates your brand’s essence. It is the first interaction between your product and potential customers, making it vital in influencing buying decisions. By integrating effective branding and graphic design elements, your blister packaging can act as a powerful tool in winning the hearts, minds, and wallets of consumers.

Usability and Consumer Experience

The effectiveness of blister packaging extends beyond protection and promotion—it’s also about enhancing consumer experience through usability. Indeed, how easy a package is to open, use, and even repurpose, can significantly impact a product’s success in the market.

Consider these points when designing for usability:

- Easy to Open: Consumers appreciate simplicity. If your blister packaging is hard to open, it could lead to frustration and negative perceptions of your brand. So, design your blister packs with easy-open features, such as perforated lines or pull tabs. This ensures that customers can access the product without any hassle, thereby enhancing their overall experience.

- Visibility of the Product: In blister packaging design, visibility is key. A clear clamshell pack or a transparent blister pack lets the customer see exactly what they’re purchasing, boosting their confidence in the product. This not only provides a sense of authenticity but also allows the consumer to inspect the product without opening the package.

- Instructions and Information: Good packaging design should also inform the consumer. Blister cards are perfect platforms to communicate instructions on how to open, use, or dispose of the product. Clear and concise information enhances the user experience and reflects positively on your brand.

- Reusability and Disposal: In an era where sustainability is valued, a package that is easy to dispose of, or better yet, reusable, can elevate your brand’s reputation. Whether it’s a clamshell pack that can double as a storage container, or packaging made from recyclable materials, incorporating sustainable practices into your blister packaging design can enhance consumer experience and perception.

Blister packaging is a powerful tool that can significantly enhance consumer experience when designed with usability in mind. By ensuring that your blister packs are easy to open, informative, and sustainable, you can create a positive interaction with your product, which in turn, leads to increased customer satisfaction and brand loyalty.

Environmental Considerations

As we delve deeper into the journey of blister packaging, one paramount aspect that we can’t ignore is its environmental impact. In today’s eco-conscious society, it’s not enough for blister packs to be functional and aesthetically pleasing. They should also be designed with environmental considerations in mind.

To begin, consider the choice of materials. PVC, a common material for blister packaging, is non-biodegradable and can cause environmental harm. However, a shift towards more eco-friendly materials, such as PET and RPET, which are recyclable, can significantly reduce the environmental footprint of your packaging.

Secondly, think about waste reduction. The design of blister packs should be optimized to minimize unnecessary material usage. Every millimeter of plastic saved equates to less waste in our landfills and oceans. From the design phase, aim to create packaging that uses just enough material to secure the product without excess.

Additionally, consider how the package can be disposed of responsibly. Adding clear instructions for disposal or recycling on the blister cards not only educates consumers about proper waste management, but it also reiterates your brand’s commitment to sustainability.

Furthermore, using energy-efficient blister packaging machines during production can lower the overall carbon footprint of your packaging process. Similarly, sourcing blister packaging supplies from local manufacturers can reduce transport-related emissions.

Lastly, consider innovations such as plant-based plastics, or biodegradable alternatives that can decompose naturally, further lessening the environmental impact.

In conclusion, while blister packaging is an essential component of product retail, its environmental implications should be thoughtfully considered. Through careful material selection, waste reduction, responsible disposal messaging, energy efficiency, and exploration of innovative materials, we can mitigate the environmental impact of blister packaging and contribute to a more sustainable future.

Legal and Regulatory Requirements

As we navigate the intricate terrain of blister packaging, we must not overlook the significant role that legal and regulatory requirements play. Each sector has its own set of packaging rules that need to be meticulously considered in the package design process.

First and foremost, for blister packaging, child-resistant regulations are key. Certain products like medications or hazardous materials demand blister packs that are specifically designed to deter access by young children. Yet, these packages must also remain accessible for adults, particularly seniors. Thus, incorporating safety features that align with regulatory requirements without compromising ease-of-use is a critical aspect of the design process.

Equally important are labeling requirements. Most retail products are required by law to have labels that clearly communicate critical information such as product ingredients, usage instructions, and safety warnings. For blister cards, ensuring that such vital details are displayed prominently and legibly is a must. More so, labels should comply with the size, color, language, and placement guidelines set by the appropriate regulatory bodies.

Next, environmental regulations also need careful consideration. In many regions, rules are in place to limit the use of certain types of plastics or to require specific recycling symbols. Making sure that your blister packaging complies with these environmental laws can save your brand from hefty fines, and more importantly, reinforces your commitment to sustainability.

Lastly, consider industry-specific standards. From the pharmaceutical industry’s strict packaging rules to the food industry’s hygiene and freshness requirements, your blister packaging design should meet all the relevant guidelines pertinent to your product’s industry.