No products in the cart.

Increases You Profits By Owning A 2-In-1 Blister Packaging Machine / Clamshell Sealer

Welcome to the forefront of retail product packaging innovation! In today’s competitive market, efficiency and presentation are key to capturing consumer attention and maximizing sales. Our focus on Blister Packaging Machinery is not just about providing state-of-the-art equipment; it’s about transforming the way your products are presented and protected. Whether you’re a manufacturer, distributor, or retailer, understanding the impact of advanced packaging solutions on your bottom line is crucial. In this blog, we delve into the world of blister and clamshell packaging machines, exploring how these technologies offer unparalleled efficiency, aesthetic appeal, and cost-effectiveness. From custom design options to streamlined production processes, our blister packaging machinery is designed to meet the diverse needs of businesses aiming to stand out in the retail landscape. Join us as we unveil the secrets to increasing profits and enhancing brand visibility through innovative packaging solutions!

📞 Call us for deep discounts on all product packaging solutions

+1-800-341-5961

We will help you increase your profits?

Get wholesale prices on all blister packaging machines & supplies!

POWERPAK Industries, LLC

Topics Covered In This Blister Packaging Machine & Clamshell Sealing Machinery Blog:

1. Benefits of Using 2-in-1 Blister Packaging and Clamshell Sealing Machines

2. Trends in Retail Product Packaging

3. Custom Packaging Solutions for Different Industries

4. The Role of Packaging in Branding and Marketing

5. How to Choose the Right Packaging Machinery and Supplies

6. Cost-Benefit Analysis of In-house Packaging vs. Outsourcing

7. Improving Product Visibility and Sales with Effective Clamshell and Blister Packaging

8. Maintenance and Upkeep of Blister and Clamshell Packaging Machines

9. Compliance and Regulatory Considerations in Packaging

10. Innovations in Blister and Clamshell Packaging Technology

Blister Packaging Supplies

Top Brands Depend On…

Enterprise Grade Blister Packaging Machines

Start-Up Businesses Can Afford

Quick Links:

Blister Packaging Supplies

Blister Packs

Clamshell Packs

No Plastic & Eco-Friendly Fold-Seal™ Packs

Blister Packaging Machines

Clamshell Packaging Machines

Custom Tooling & More!

1. Benefits of Using A 2-in-1 Blister Packaging Machine and Clamshell Sealing Machine

In the dynamic world of retail product packaging, the efficiency and versatility of your equipment are paramount. Our 2-in-1 Blister Packaging and Clamshell Sealing Machines stand at the forefront of this revolution, offering a multitude of benefits to manufacturers, producers, distributors, and sellers.

Here’s how this innovative blister packaging machine can elevate your packaging process:

- Dual Functionality: With the capability to perform both blister packaging and clamshell sealing, these machines are a game-changer. This dual feature not only streamlines the packaging process but also reduces the need for multiple machines, saving valuable floor space and capital investment.

- Cost-Effective Operations: By integrating two essential functions into one machine, our blister packaging machinery significantly cuts down on operational costs. Less manual labor, reduced energy consumption, and minimal maintenance requirements contribute to a more cost-efficient production line.

- Enhanced Product Quality: The precision and consistency delivered by our blister and clamshell packaging machines ensure that each product is securely and attractively packaged. This high-quality packaging not only protects the product but also enhances its shelf appeal, crucial for attracting customers in both e-commerce platforms and brick-and-mortar stores.

- Customization and Flexibility: Catering to the diverse needs of various products, our machinery offers customization options in sizing, design, and functionality. Whether it’s unique blister packs, eye-catching clamshell packs, or specialized blister cards, our equipment is capable of handling a wide range of packaging needs.

By incorporating these advanced 2-in-1 blister packaging and clamshell sealing machines into your production line, you’re not just investing in equipment; you’re investing in a solution that propels your business towards greater profitability and market competitiveness. As you explore the myriad of blister packaging and clamshell packaging supplies available, remember that choosing a machine that excels in both blister packaging and clamshell sealing is key to achieving optimal efficiency and quality in your packaging endeavors.

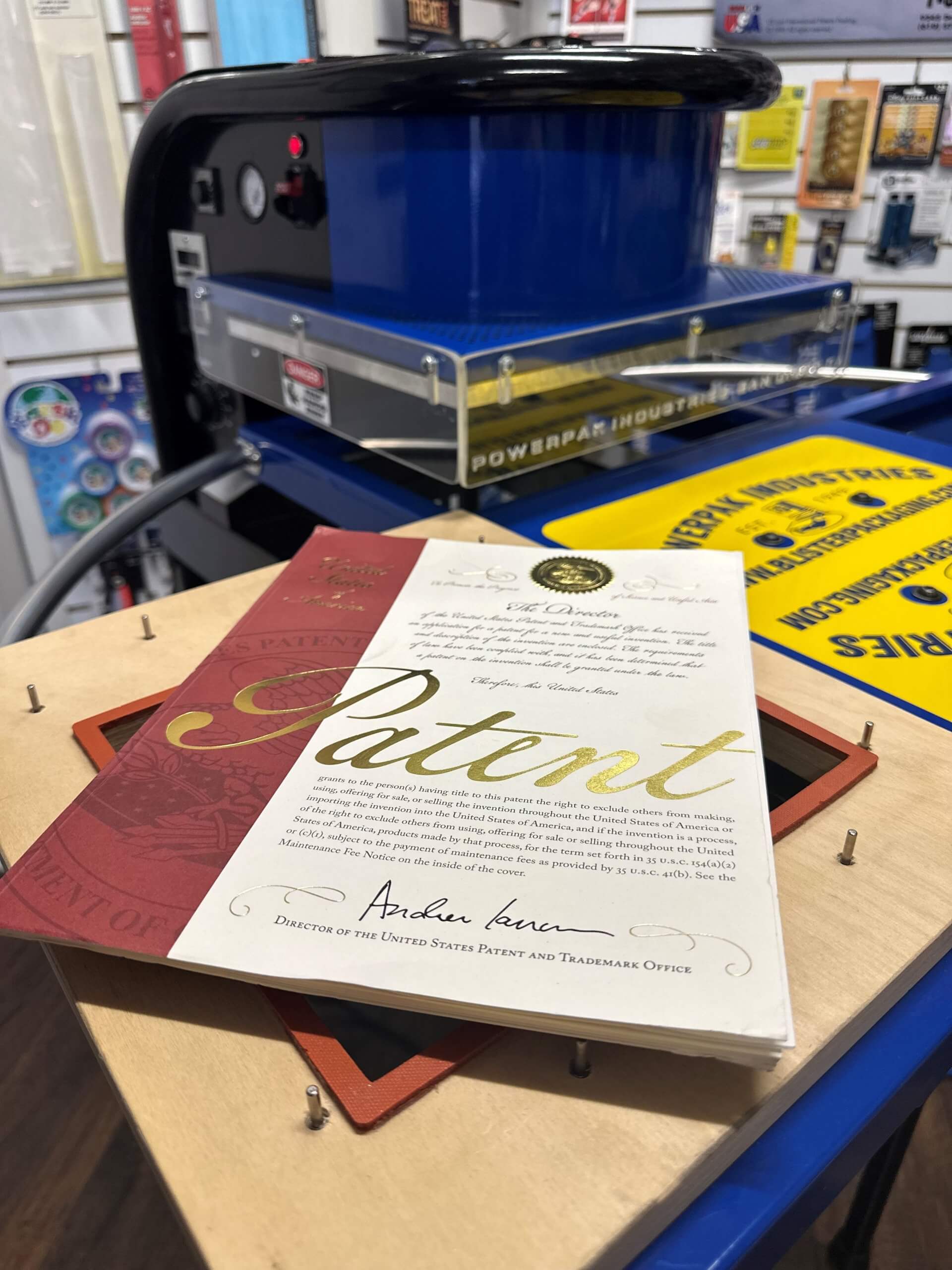

Blister Packaging Machine & Clamshell Sealer

Fully Customizable & Portable

POWERPAK’s Original

2-in-1

Blister Packaging Machine / Clamshell Packaging Machine

2. Trends in Retail Product Packaging

In the ever-evolving landscape of retail product packaging, staying abreast of current trends is crucial for success. Our blister packaging machinery and clamshell packaging machines are designed to align seamlessly with these emerging trends, ensuring your products stand out in the market.

Here’s how our solutions cater to the latest packaging trends:

- Sustainability: Environmental consciousness is at the forefront of packaging innovation. Our machines support eco-friendly materials, enabling you to use sustainable blister packs and clamshell packs. This alignment with green initiatives not only appeals to environmentally conscious consumers but also demonstrates your commitment to responsible practices.

- Innovative Designs: In the realm of blister packaging and clamshell packaging, creativity is key. Our equipment allows for the creation of unique, eye-catching designs that captivate consumers’ attention. Customizable options in blister packs and clamshell packs mean your products can be packaged in a way that highlights their best features, enhancing visual appeal and marketability.

- Consumer Preferences: Understanding and responding to consumer preferences is essential. Our blister packaging and clamshell sealing machines cater to the demand for secure, tamper-evident, and easy-to-open packaging. This not only improves the consumer experience but also builds trust and loyalty towards your brand.

- Adaptability and Versatility: The ability to quickly adapt to changing market demands is a significant advantage. Our blister packaging machines and clamshell packaging machines are versatile, handling a variety of materials and product sizes. This adaptability ensures you can respond rapidly to market trends and consumer needs.

By integrating our advanced blister packaging and clamshell sealing solutions into your production process, you’re not only staying ahead of industry trends but also enhancing your product’s appeal and market presence. Remember, choosing machines that efficiently perform both blister packaging and clamshell sealing in one is a strategic move towards efficiency, innovation, and consumer satisfaction. With our cutting-edge machinery, you’re equipped to lead the way in retail product packaging, driving increased sales and higher profit margins.

3. Custom Packaging Solutions for Different Industries

Tailored packaging solutions are vital in meeting the diverse requirements of various industries. Our blister packaging machinery and clamshell packaging machines are not just tools; they are the gateway to customized, industry-specific packaging success.

Here’s how we cater to different sectors:

- Fishing Lure Packaging: In the fishing industry, packaging not only needs to be functional but also visually appealing to attract enthusiasts. Our blister packaging machinery and clamshell packaging machines excel in creating durable and attractive packaging for fishing lures. These packages provide clear visibility of the lures, protect them from damage, and can be customized with captivating graphics and designs. This level of customization is crucial for standing out in a competitive market, where the presentation of fishing lures can significantly influence a buyer’s decision. With our packaging solutions, your fishing lures will not only be well-protected but also presented in a way that appeals to the fishing community, enhancing both product value and customer engagement.

- Cosmetics and Personal Care: In the world of beauty products, packaging plays a critical role in brand perception. Our blister and clamshell packaging solutions allow for stunning visual designs and secure encasing of delicate items, enhancing brand appeal and customer trust.

- Electronics and Consumer Goods: The electronics sector requires packaging that protects against damage and static. Our blister packaging machines provide robust and reliable packaging solutions, ensuring that electronic products are safely transported and displayed.

- Food and Beverage: Our packaging machines are versatile enough to handle the unique demands of food and beverage products. From single-serve portions to bulk packaging, we provide solutions that maintain freshness, comply with food safety regulations, and attract consumer attention.

By choosing our blister packaging machinery and clamshell packaging machines, industries ranging from pharmaceuticals to electronics benefit from custom solutions tailored to their specific needs. Whether it’s ensuring the safety of medications or enhancing the allure of cosmetics, our machines provide the flexibility, reliability, and customization necessary to thrive in today’s market. Remember, the right packaging can make all the difference in how your product is perceived and, ultimately, its success in the marketplace. Let our blister packaging and clamshell sealing solutions be the key to unlocking your product’s potential.

Flip Sealer Packaging Machine:

Clamshell Packaging Machine & Blister Pack Sealer

POWERPAK’s Flip Sealer:

A 2-in-1 Clamshell Packaging Machine & Blister Packaging Machine

4. The Role of Packaging in Branding and Marketing

Effective packaging is a powerful tool in branding and marketing, playing a crucial role in how consumers perceive and interact with your products. Our blister packaging machinery and clamshell packaging machines are designed to elevate your brand’s visibility and appeal.

Here’s how:

- First Impressions Count: Packaging is often the first physical interaction a customer has with your product. Our blister packs and clamshell packs are designed to make a striking first impression, showcasing your product in a clear, attractive manner that invites consumer interest and trust.

- Brand Identity Enhancement: Custom designs and graphics are vital in establishing and reinforcing your brand identity. Our packaging solutions offer extensive customization options, allowing you to incorporate brand colors, logos, and unique designs that resonate with your target audience and distinguish your products on the shelves.

- Influencing Consumer Decisions: Well-designed packaging can significantly influence purchasing decisions. The quality, functionality, and aesthetics of our blister and clamshell packaging not only protect your product but also enhance its perceived value, making it more appealing to potential buyers.

- Marketing and Promotional Opportunities: Packaging is an essential element of your marketing strategy. Our blister packaging and clamshell sealing machines enable you to create packaging that serves as a marketing tool, communicating key product information, and promotional messages effectively.

Investing in our blister packaging machinery and clamshell packaging machines means more than just acquiring equipment; it’s about embracing a packaging solution that bolsters your branding and marketing efforts. By focusing on custom designs, graphic elements, and the overall quality of your packaging, you position your products to stand out in the competitive retail landscape, driving increased sales and enhancing profit margins. Remember, in the world of retail, packaging is not just a container—it’s a powerful brand ambassador.

5. How to Choose the Right Packaging Machinery and Supplies

Selecting the appropriate blister packaging machinery and supplies is crucial for your product’s success. The right equipment and materials not only enhance efficiency and product appeal but also significantly impact your bottom line.

Here’s a guide to making informed choices:

- Assess Your Product Requirements: Understand the specific needs of your product, including size, shape, and material sensitivity. This assessment helps in choosing machinery like blister packaging machines or clamshell packaging machines that can handle your product’s unique requirements.

- Consider Production Volume: Your production volume dictates the type of packaging machine needed. Our range includes options suitable for both high-volume production and smaller, more specialized runs. This flexibility ensures you invest in machinery that aligns with your current and future production needs.

- Quality of Materials: The quality of blister packs, clamshell packs, and other packaging supplies is paramount. We offer high-quality materials that protect your product while enhancing its visual appeal, crucial for standing out in the retail environment.

- Customization Capabilities: Our blister packaging and clamshell sealing machines offer extensive customization options. Whether it’s custom sizing, graphic designs, or blister card creations, the ability to tailor your packaging to your product’s specific needs is a game-changer.

- Cost-Effectiveness and ROI: Consider the long-term cost-effectiveness and potential return on investment when selecting your packaging machinery. Our machines are designed to be efficient and durable, offering a great balance between initial investment and long-term benefits.

By focusing on these key factors, you can confidently choose the blister packaging machinery and supplies that best fit your product’s needs and your business’s goals. Remember, the right packaging solution not only protects your product but also plays a crucial role in its market success. Our commitment to providing versatile, high-quality packaging solutions ensures that you have access to the best tools to increase your profit margins and strengthen your brand’s presence in the market.

6. Cost-Benefit Analysis of In-house Packaging vs. Outsourcing

Deciding between in-house packaging and outsourcing is a pivotal choice for businesses aiming to optimize costs and maintain control over product presentation. Our blister packaging machinery and clamshell packaging machines play a critical role in this decision-making process.

Here’s a breakdown of the cost-benefit analysis:

- Control Over Quality and Branding: In-house packaging with our blister packaging and clamshell sealing machines gives you complete control over the quality and appearance of your product packaging. This direct oversight ensures consistency in branding and quality, critical factors in building customer trust and loyalty.

- Cost Savings in the Long Term: Initial investment in blister packaging machinery may be higher compared to outsourcing, but the long-term savings are significant. In-house packaging eliminates ongoing service fees, reduces transportation costs, and provides the flexibility to adapt to changing packaging needs without additional expenses.

- Flexibility and Responsiveness: Owning your packaging equipment allows for greater flexibility in production scheduling and quicker response to market changes. This agility is crucial in today’s fast-paced retail environment, where timely product launches and adaptations can set you apart from competitors.

- Reduced Dependency on External Suppliers: Relying on external packaging services can introduce risks, including potential delays and lack of control over the packaging process. In-house packaging with our machinery minimizes these risks, ensuring a more reliable and streamlined operation.

While outsourcing may appear more cost-effective initially, the benefits of in-house packaging using blister packaging machines and clamshell packaging machines become apparent when considering long-term cost savings, quality control, flexibility, and brand integrity. Investing in our packaging solutions empowers your business to take charge of the entire packaging process, ultimately contributing to increased profit margins and a stronger market presence. Remember, the choice of packaging strategy is not just about cost—it’s about investing in the future of your brand.

7. Improving Product Visibility and Sales with Effective Clamshell and Blister Packaging

Effective clamshell and blister packaging plays a pivotal role in enhancing product visibility and boosting sales in both e-commerce and brick-and-mortar settings. Our blister packaging machinery and clamshell packaging machines are key to achieving this.

Here’s how well-designed packaging makes a difference:

- Showcasing Product Features: Clarity and visibility are essential. Our blister packs and clamshell packs offer a clear view of the product, allowing customers to see what they are buying without opening the packaging. This transparency builds trust and facilitates purchase decisions, especially in a physical retail setting.

- Enhancing Online Presence: In the e-commerce world, packaging becomes part of the product imagery. Our blister packaging and clamshell packaging solutions provide aesthetically pleasing, camera-ready packaging that stands out in online product listings, making your items more clickable and desirable.

- Brand Differentiation: Unique packaging designs, enabled by our custom packaging solutions, help differentiate your product from competitors. Whether it’s through innovative shapes, custom graphics, or unique blister cards, our packaging machines allow for creativity that captures consumer attention.

- Protection and Durability: Beyond visual appeal, our packaging solutions offer superior protection, ensuring that products reach customers in perfect condition. This is crucial for maintaining a positive brand reputation and reducing returns due to damage.

- Eco-Friendly Options: As consumers become more environmentally conscious, offering sustainable packaging options can enhance your brand’s appeal. Our machines are capable of working with eco-friendly materials, allowing you to tap into this growing market segment.

Investing in our blister packaging machinery and clamshell packaging machines means investing in your product’s market appeal and sales potential. By focusing on visibility, online presence, differentiation, protection, and sustainability, you set your products up for success in both digital and physical retail spaces. Remember, the right packaging is not just a protective casing—it’s a marketing tool that can significantly influence consumer perception and buying behavior.

8. Maintenance and Upkeep of Blister Packaging Machine and Clamshell Packaging Machines

Proper maintenance and upkeep of your blister packaging machinery and clamshell packaging machines are essential for ensuring their longevity and consistent performance.

Here are some best practices to keep your packaging equipment in top condition:

- Regular Cleaning and Inspection: Routine cleaning and inspection of your blister packaging and clamshell sealing machines are crucial. Removing debris and checking for wear and tear help prevent breakdowns and extend the lifespan of the machinery.

- Follow Manufacturer’s Maintenance Schedule: Adhere to the maintenance schedule recommended by the manufacturer. Regular servicing, including lubrication and part replacements, ensures that your blister pack machine and clamshell pack machine operate efficiently and reliably.

- Train Your Staff: Proper training for operators is key. Ensure that your staff knows how to operate the machines correctly and are aware of the maintenance procedures. Well-trained personnel can detect potential issues early, preventing major malfunctions.

- Use Quality Supplies: The longevity of your packaging machines also depends on the quality of the blister packs, clamshell packs, and other supplies you use. Opting for high-quality materials reduces wear on the machinery and ensures smoother operations.

- Keep Spare Parts Handy: Having a stock of essential spare parts for your blister sealing machine and clamshell sealing machine can save time during unexpected breakdowns. Quick replacements keep your production line running with minimal downtime.

By implementing these maintenance and upkeep practices, you not only ensure the efficient functioning of your blister packaging machinery and clamshell packaging machines but also maximize their return on investment. Regular maintenance contributes to consistent packaging quality, reduces the risk of costly repairs, and upholds your reputation for delivering top-tier packaged products. Remember, well-maintained packaging equipment is the backbone of a successful packaging operation, directly impacting your profitability and customer satisfaction.

9. Compliance and Regulatory Considerations in Packaging

Navigating the complex landscape of packaging regulations and compliance is crucial for manufacturers, producers, and distributors. Our blister packaging machinery and clamshell packaging machines are designed to meet these rigorous standards, ensuring your products comply with industry-specific regulations.

Here’s how our solutions address compliance concerns:

- Adherence to Industry Standards: Different industries have unique packaging regulations. Our equipment is engineered to comply with these standards, whether it’s for pharmaceuticals, food and beverage, electronics, or consumer goods. This compliance ensures that your products meet legal requirements and consumer safety standards.

- Material Safety and Quality: We prioritize the use of high-quality and safe materials in our blister packs, clamshell packs, and other packaging supplies. This focus on material safety is essential for industries where packaging directly impacts product integrity, such as in pharmaceuticals and food products.

- Customizable for Specific Regulations: Our packaging solutions offer the flexibility to customize packaging according to specific regulatory requirements. Whether it’s child-resistant features, tamper-evident designs, or specific labeling requirements, our machines are capable of accommodating these needs.

- Eco-Friendly and Sustainable Options: With increasing emphasis on environmental regulations, our machines support eco-friendly packaging options. This capability allows you to align with sustainability standards and cater to the growing market of environmentally conscious consumers.

Ensuring compliance with packaging regulations is not just about avoiding legal pitfalls; it’s about building consumer trust and safeguarding your brand reputation. By choosing our blister packaging machinery and clamshell packaging machines, you equip your business with the tools necessary to navigate these regulations effectively, enhancing your product’s marketability and consumer appeal. Remember, in a world where packaging standards are constantly evolving, having equipment that meets these demands is a significant competitive advantage, contributing to your overall business success and profitability.

10. Innovations in Blister and Clamshell Packaging Technology

The blister and clamshell packaging industry is continuously evolving with technological advancements that significantly benefit users in terms of efficiency, customization, and eco-friendliness. Our latest blister packaging machinery and clamshell packaging machines are at the forefront of these innovations.

Here’s how they are transforming the packaging world:

- Enhanced Efficiency: Our state-of-the-art machines are designed for speed and precision, significantly reducing packaging time and increasing throughput. This efficiency is vital for businesses looking to scale up production without compromising on quality.

- Advanced Customization Options: Customization is key in today’s market. Our equipment offers extensive customization capabilities, from unique blister pack shapes to specialized clamshell designs. This flexibility allows for tailor-made packaging solutions that perfectly fit your product and branding needs.

- Eco-Friendly Solutions: Environmental sustainability is more important than ever. Our machines support the use of eco-friendly materials, enabling you to produce packaging that is not only attractive but also aligns with green initiatives. This feature is particularly appealing to the growing segment of eco-conscious consumers.

- User-Friendly Interfaces and Automation: While omitting detailed automation topics, it’s worth noting that our machines are equipped with user-friendly interfaces. These interfaces simplify the packaging process, making it easier for operators to manage production with minimal training.

- Durability and Longevity: Built to last, our blister packaging and clamshell sealing machines are made with high-quality components. This durability ensures that your investment continues to deliver value over the years, with minimal maintenance required.

By incorporating these innovative features into our blister packaging machinery and clamshell packaging machines, we provide solutions that not only meet but exceed the expectations of today’s packaging industry. Whether you’re a small start-up or a large-scale producer, our advanced technology is designed to boost your efficiency, cater to your unique packaging needs, and align with environmental standards, all of which contribute to increasing your profit margins and enhancing your brand’s market presence. Remember, investing in cutting-edge packaging technology is not just about enhancing operations—it’s about shaping the future of your brand in the competitive marketplace.