Action Figure Blister Packaging | Blister Packaging for Toys & Hot Wheels

Check out our blister packaging Machine

The only thing you will be needing for your packging

SHOW MESHARE THIS

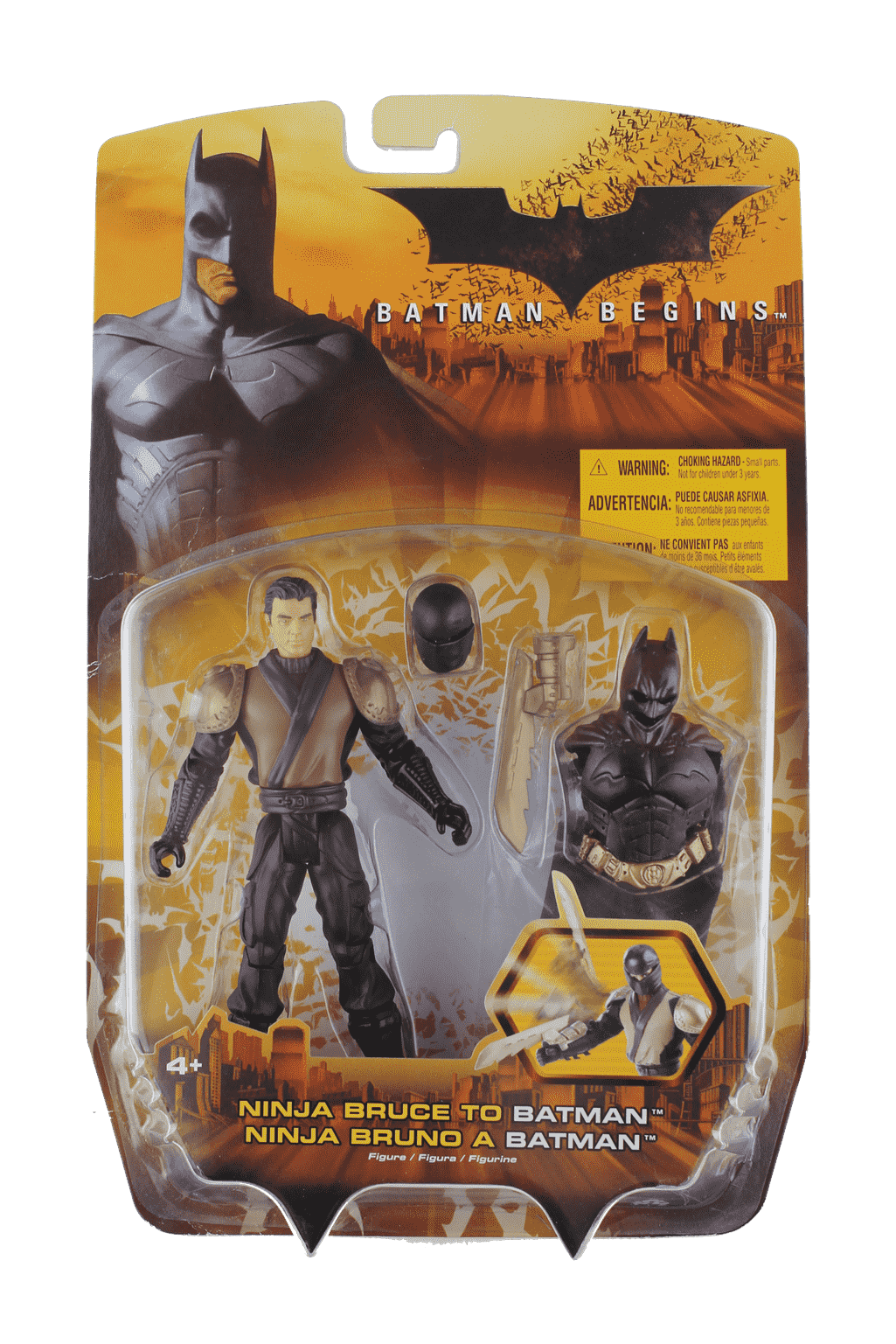

The toy industry depends on packaging that protects products while showcasing them attractively. Even small imperfections can impact sales, making blister packaging a top choice for toy manufacturers. These durable, clear systems protect valuable toys throughout shipping and display while enhancing shelf presence. With the right design, smart packaging elevates everyday toys into premium, eye-catching retail products. 📞 Call us for deep discounts on all product packaging solutions +1-800-341-5961 We will help you increase your profits? Get wholesale prices on all blister packaging machines & supplies! POWERPAK Industries, LLC 1. Why is Packaging Important in the Toy and Game Industry? Blister packaging plays a...

The toy industry depends on packaging that protects products while showcasing them attractively. Even small imperfections can impact sales, making blister packaging a top choice for toy manufacturers. These durable, clear systems protect valuable toys throughout shipping and display while enhancing shelf presence. With the right design, smart packaging elevates everyday toys into premium, eye-catching retail products.

📞 Call us for deep discounts on all product packaging solutions

+1-800-341-5961

We will help you increase your profits?

Get wholesale prices on all blister packaging machines & supplies!

POWERPAK Industries, LLC

1. Why is Packaging Important in the Toy and Game Industry?

Blister packaging plays a major role in influencing purchasing decisions, especially in retail environments where parents and children rely on first impressions. Its clear visibility allows shoppers to see the toy in full detail, building trust and confidence in the product. Professional, well-designed packaging communicates quality and safety, helping toys stand out as reliable and desirable choices on crowded store shelves.

1.1 Safety and Protection Benefits

Sealed packaging protects toys from contamination caused by handling, dust, moisture, and temperature fluctuations. Individual compartments keep components neatly organized and prevent small parts from getting lost. Tamper-evident features add an extra layer of security, ensuring every product reaches the customer in perfect, factory-sealed condition.

1.2 Marketing and Brand Recognition

Eye-catching packaging designs capture attention in busy retail aisles and strengthen brand recognition across multiple product lines. A polished, premium presentation not only enhances perceived value but also supports higher price points in competitive markets. Generous graphics space provides room to highlight character details, play features, and branding elements that engage both children and parents at first glance.

1.3 Retail Display Advantages

This packaging format supports efficient pegboard merchandising with hanging designs that make the most of limited retail floor space. Stackable configurations enable clean, high-impact bulk displays ideal for promotions or seasonal sales. The use of clear materials highlights toy colors, shapes, and intricate details—enhancing visibility and appeal while keeping products organized and accessible.

2. Is it Cheaper to Outsource Blister Packaging for Toys or Buy a Machine?

Cost analysis depends on production volume and business goals, with different approaches serving various operational requirements.

2.1 Outsourcing Benefits for Small Operations

Outsourcing your packaging isn’t a bad thing—it really comes down to what works best for your business model. Many companies choose to outsource because it eliminates the need to manage equipment, labor, and space. It’s convenient, especially when you’re just getting started or dealing with low production volumes.

However, contract packaging can become expensive over time—often costing around $0.50 per pack just for labor. For businesses producing moderate to high volumes, that cost adds up quickly. By investing in one of Powerpak’s machines, you gain control over your production, reduce per-unit costs, and often see your return on investment pay for itself in the long run.

One of the biggest advantages of Powerpak is the range of equipment we offer. If you’re just starting out, we have inexpensive entry-level machines starting around $200, perfect for small-scale operations or testing new product lines. As your business grows, you can easily upgrade to larger, automated systems—so you only invest at the level that fits your current needs.

In short: outsourcing offers convenience, but owning a Powerpak machine gives you control, flexibility, and long-term savings—with options for every budget and business size.

2.2 In-House Equipment Advantages

Investing in in-house packaging equipment offers a wide range of advantages that go beyond simple cost savings. While outsourcing may seem convenient at first, owning your own equipment quickly becomes the more efficient and profitable choice over time. Once the machine is paid for, your per-unit packaging costs drop dramatically—eliminating ongoing fees that can reach $0.50 or more per pack when using contract packagers.

Having your own equipment also means complete control over production schedules. You can run jobs whenever needed, respond to last-minute orders, and meet tight deadlines without relying on external vendors. This flexibility allows you to adapt quickly to seasonal demand, product launches, or sudden spikes in volume.

Quality control is another key benefit. In-house operations ensure consistent sealing, alignment, and presentation across every batch, reinforcing your brand’s reputation for reliability and professionalism. It also provides the freedom to test new designs, materials, or package formats on the spot—without added setup fees or waiting times.

Financially, the long-term savings speak for themselves. By cutting out third-party labor and handling costs, you retain more profit per packaged product. Over time, this increased efficiency allows the equipment to pay for itself.

Powerpak machines are also designed with scalability in mind. We offer affordable entry-level systems starting around $200, ideal for startups or smaller operations, with the option to upgrade as production needs grow. Keeping packaging in-house not only strengthens consistency and profitability but also provides security, reliability, and full control over your entire process from start to finish.

3. What Types of Blister Packaging are Best for Toys (Clamshell, Carded, Trapped Blister)?

Different packaging types serve various product requirements, with each format offering specific advantages for different applications.

3.1 Clamshell Packaging Systems

Clamshell packaging offers maximum product protection with a hinged design that lets customers examine the product without opening the package. Its secure closure mechanisms help prevent theft and tampering, while the clear, polished appearance gives products a premium look that supports higher retail pricing.

Best for: Action figures, collectible toys, and electronic games.

Cost range: $0.25–$0.75 per package.

Tooling investment: Typically $3,000–$8,000, though no tooling cost is required when using one of our hundreds of stock blister molds.

4.2 Carded Blister Solutions

Cardboard-backed packaging provides a cost-effective and visually appealing solution that balances protection with strong branding potential. The printed card offers generous space for character artwork, product information, and play scenarios, while hanging holes allow for easy pegboard display in retail environments. This format is ideal for mass-market applications where affordability and presentation both matter.

Ideal for: Small toys, accessories, and basic action figures.

Price range: $0.15–$0.30 per package, depending on volume.

Setup costs: $250–$750.

4.3 Trapped Blister Formats

Trapped blister packaging securely seals products between a clear plastic front and a printed backing card using heat, forming a tamper-evident closure around the edges. This format provides excellent visibility while keeping items firmly in place, making it ideal for heavier products that need extra support. It balances protection, presentation, and cost efficiency—showcasing toys and accessories with a premium, professional finish.

Perfect for: Heavier items such as Hot Wheels, toy cars, and collectibles.

Cost range: $0.10–$0.40 per unit.

Tooling investment: $250–$750.

5. How Can Blister Packaging Improve the Shelf Appeal and Retail Visibility of Toy Products?

Strategic design elements drive purchasing decisions and enhance retail performance.

5.1 Visual Impact Strategies

Crystal-clear plastic materials maximize visibility, allowing customers to see every detail of the product at a glance. Vibrant backing cards enhance shelf appeal, while character-focused graphics instantly capture the attention of target age groups. Thoughtful window placement draws focus to key product features, creating a dynamic, high-impact presentation that stands out in any retail environment.

5.2 Brand Recognition Elements

Consistent packaging strengthens brand loyalty across entire product lines, creating a unified look that customers instantly recognize. Strategic logo placement reinforces brand identity throughout collections, while coordinated color schemes align with character themes and popular franchises. Using premium materials enhances perceived quality and value, helping products stand out and appeal to both collectors and casual buyers alike.

5.3 Information Communication

Package space serves as an engaging storytelling tool, featuring character backstories and imaginative play scenarios that draw children into the product experience. Clear feature callouts highlight special functions and included accessories, helping shoppers understand what makes the toy unique. Age recommendations support informed purchasing decisions, while prominently displayed safety information reassures parents and builds trust in the brand.

6. What’s the Difference Between Semi-Automatic and Fully Automatic Blister Packaging Machines for Toys?

Understanding automation levels helps optimize equipment selection decisions.

6.1 Semi-Automatic System Features

ChatGPT said:

Our 4-Station Blister/Clamshell Sealer is a proven favorite in the toy industry because it strikes the perfect balance between speed, reliability, and simplicity. Designed for efficiency, this machine can package 3,000 to 4,000 packs per hour, depending on how many cavities (or “ups”) are run at once. That makes it ideal for medium to high production volumes—fast enough to keep up with demand, yet simple enough for everyday operation without complex programming or maintenance.

Unlike fully automated systems, the 4-Station model gives you greater control and fewer complications. Fully automated lines may seem appealing at first, but they come with far more moving parts, electronics, and sensors—each one representing a potential point of failure. When something breaks or goes out of alignment, production can come to a complete stop, often requiring specialized technicians or expensive repairs to get running again.

In contrast, our 4-Station Sealer is mechanically straightforward and built to last. It’s easy to operate, simple to maintain, and highly dependable, with minimal downtime between runs. While a fully automated system can cost two to three times more, the 4-Station delivers similar throughput at a fraction of the price—making it the smarter investment for most manufacturers.

With Powerpak’s 4-Station Sealer, you get the best of both worlds: high-speed production, long-term reliability, and a lower cost of ownership—all engineered specifically for the demanding pace of toy packaging.

6.2 Fully Automatic Disadvantages

ChatGPT said:

Fully automatic packaging systems may sound appealing for their promise of “hands-free” operation, but in reality, they often come with several major drawbacks—especially when compared to Powerpak’s 4-Station Sealer.

First, cost is the biggest factor. Fully automated systems can cost three times as much as a Powerpak machine, representing a huge upfront investment before you even begin production. That high price doesn’t always translate to efficiency—especially if your packaging needs change, or if you’re not running large-scale, nonstop production every day.

Second, complexity becomes a serious issue. Fully automatic systems are packed with sensors, servo motors, and integrated robotics. Each of these components introduces another potential failure point. When one part malfunctions, the entire line can shut down, and diagnosing the problem often requires specialized technicians or proprietary parts. This leads to longer downtime and higher repair costs, eating away at the efficiency the system is supposed to provide.

Third, maintenance and training are far more demanding. Operators need advanced training just to run and troubleshoot automated systems, and regular calibration is often required to keep everything in sync. The more automation you add, the more time and expertise you need to maintain it.

In contrast, Powerpak’s 4-Station Sealer delivers comparable output—3,000 to 4,000 packs per hour—at a fraction of the price. It’s mechanically simple, easy to operate, and designed for dependable, consistent performance without all the high-maintenance headaches of a fully automatic system. For most manufacturers, it’s the smarter, more cost-effective solution that keeps production fast, flexible, and reliable.

6.3 Hybrid Solutions

Combination systems offer flexibility with higher productivity through automated feeding combined with manual quality inspection options. Costs balance between semi and fully automatic systems, creating the ideal compromise for growing manufacturers.

7. How do I Make Blister Packaging Eco-Friendly Without Increasing Costs?

Sustainable packaging appeals to environmentally conscious consumers while green initiatives can reduce costs and improve appeal.

7.1 Material Selection Strategies

Recyclable PET plastic combines exceptional clarity with strong environmental benefits, offering a clear view of the product while supporting sustainable packaging initiatives. By reducing material thickness, manufacturers can maintain product protection while lowering both material use and costs. As bio-based plastics scale into volume production, their pricing becomes increasingly competitive, offering an eco-friendly alternative without compromising performance. Additionally, incorporating post-consumer recycled content further reduces raw material expenses and minimizes environmental impact—creating a packaging solution that’s both efficient and responsible.

7.2 Design Optimization Methods

Right-sized packaging optimizes material use by eliminating excess space without sacrificing product protection. Streamlined layouts minimize waste during production, improving both efficiency and sustainability. Using mono-material designs makes recycling easier for consumers and simplifies the manufacturing process. This reduction in material variety and complexity also helps lower production costs while maintaining durability and visual appeal.

8. Blister Packaging for Cars and Vehicle Toys

Vehicle toy packaging requires special considerations for wheels, with industry-leading standards for protection.

8.1 Wheel and Axle Protection

Custom-formed cavities keep wheels securely in place, preventing damage and maintaining perfect alignment during shipping and handling. The clear plastic exterior highlights paint finishes and intricate decorative details, giving customers a full view of the product. Anti-static materials further protect die-cast metal surfaces from dust attraction and surface wear, ensuring each piece arrives in flawless, display-ready condition.

8.2 Scale Model Considerations

Different model scales demand specialized packaging design and protection levels. Smaller 1:64 scale items require tightly fitted cavities to keep them secure and prevent shifting, while larger models need reinforced structures to support additional weight and maintain integrity during transport. For collector or limited-edition releases, premium packaging materials and finishes are well worth the investment—enhancing perceived value, safeguarding intricate details, and appealing directly to serious enthusiasts.

9. Specialized Blister Packaging Applications

Different toy categories need unique solutions, each with specific requirements and challenges.

9.1 Blister Packaging for Dolls

Doll packaging is carefully designed to protect delicate features while enhancing visual appeal on the shelf. Clear window panels showcase facial expressions, hairstyles, and outfit details, allowing customers to appreciate the craftsmanship before purchase. Specialized hair protection keeps styles intact and prevents tangling during shipping or handling, while accessory compartments ensure small items stay neatly organized and secure.

Fashion dolls often require larger cavities to display dresses fully and provide enough room for hair volume without compression. Each accessory is given its own compartment for presentation and convenience. Using premium materials and refined finishes not only elevates appearance but also reinforces the collectible value—making the packaging an integral part of the overall product experience.

9.3 Blister Packaging Toy Animals

Animal toy packaging is designed to highlight realism and detail while offering strong protection. Clear materials allow customers to see fur textures, color patterns, and sculpted features up close, while multiple viewing angles emphasize articulation and natural poses. Educational information printed on backing cards adds value by teaching about species, habitats, or fun facts that engage both children and parents.

For plush animals, compression-resistant packaging helps maintain shape and softness through shipping and display. Realistic or collectible animal figures require secure positioning to preserve their intended pose and protect delicate features. Collector editions often justify premium packaging, complete with certificates of authenticity or specialty finishes that enhance perceived value and create a high-end unboxing experience.

10. Quality Control in Toy Blister Packaging Operations

Consistent quality ensures customer satisfaction and brand protection through rigorous standards.

10.1 Seal Integrity Testing

Strong heat seals ensure packages remain securely closed during handling, preventing accidental openings or product loss. Visual inspections identify any defects before shipping, guaranteeing consistent quality for customers. Continuous temperature monitoring throughout production maintains proper sealing conditions, while detailed quality records document performance trends over time—supporting consistent reliability and long-term process improvement.

10.2 Safety Compliance Verification

Sharp edge detection ensures packaging materials are safe to handle, preventing potential injury to consumers during opening or use. Rigorous material testing verifies CPSIA compliance, confirming that all components meet established child safety standards. Accurate age grading helps ensure products are marketed appropriately and safely for their intended age groups. Comprehensive documentation further validates regulatory compliance, giving retailers and parents confidence in both the product’s safety and the manufacturer’s commitment to quality.

11. Cost Analysis for Toy Blister Packaging

Understanding pricing helps with budget planning and profitability analysis across different volume requirements.

11.1 Small Volume Pricing

The average cost of a low-volume toy blister pack typically ranges from $0.15 to $0.50 per package, depending on the size, material thickness, and overall design complexity. Simpler front-face seal styles tend to fall on the lower end of the range, while clamshell or trapped blister formats with printed cards and custom tooling are closer to the higher end. These options provide professional, protective packaging for small to mid-size production runs while keeping costs manageable.

11.2 Medium Volume Economics

Mid-volume orders ranging from 25,000 to 100,000 units typically cost between $0.12 and $0.35 per package, depending on the style and materials used. At this scale, economies of scale significantly lower per-unit costs, making production far more efficient. Custom graphics and printing also become more affordable with higher quantities, while dedicated tooling enhances precision, consistency, and overall presentation quality—resulting in a professional, retail-ready finish at a highly competitive price point.

11.3 High Volume Advantages

Large-volume orders of 250,000 units or more typically achieve pricing between $0.05 and $0.10 per package, depending on design complexity, material selection, and tooling requirements. At this scale, automated production drastically reduces labor costs per unit, delivering exceptional efficiency and consistency. Long-term contracts provide additional cost advantages through bulk material purchasing and repeat production. The result is high-quality, professional packaging that maintains premium presentation standards while offering outstanding overall value.

12. POWERPAK Industries: Your Trusted Toy Packaging Partner

POWERPAK Industries leads the industry with decades of experience serving over 500 trusted brands, specializing in action figure and toy solutions.

12.1 Advanced Toy Packaging Technology

Our state-of-the-art facilities feature advanced manufacturing and packaging equipment designed for precision, consistency, and safety. This includes The Original 4-Station Blister/Clamshell Sealer, high-speed customizable systems, and Clean Room Model systems engineered for sensitive applications. Every Powerpak machine meets strict toy safety standards and undergoes rigorous testing, validation, and quality assurance to ensure reliable performance, product safety, and compliance with global regulations.

12.2 Customizable Solutions for Toy Industry

We provide packaging solutions that seamlessly combine protection and visual appeal, offering fully customizable designs that elevate your brand presence. Our systems deliver superior product protection with enhanced visibility through innovative, display-ready designs. For added security, we offer tamper-proof options ideal for sensitive or high-value products, along with eco-friendly alternatives for brands committed to sustainability and environmental responsibility.

12.3 Industry Expertise in Toy Markets

Our expertise spans the full spectrum of the toy industry—from action figures to vehicles—allowing us to deliver packaging solutions tailored to each category’s unique needs. We provide advanced safety features for action figures, premium presentation for collector dolls, and protective designs for toy vehicles that ensure flawless display and damage-free delivery. For toy guns, we supply secure packaging that meets strict safety regulations, while our professional animal toy packaging highlights realistic textures and details. Each solution reflects Powerpak’s commitment to combining protection, presentation, and compliance across every product line.

Frequently Asked Questions

1. What is action figure packaging blister technology?

This technology forms durable, protective plastic bubbles around toys, ensuring both product safety and professional presentation. The clear packaging enhances visibility while providing secure, tamper-resistant protection and easy retail handling. Integrated automation streamlines the entire process—forming, sealing, and cutting—to deliver consistent, high-speed production with precise, repeatable results that meet the demands of modern toy manufacturing.

2. What makes blister packaging ideal for toys?

It provides crystal-clear visibility that allows customers to see every detail of the toy, from colors to accessories, while rigid plastic shells protect delicate components from damage during handling and transport. Sealed barriers keep out dust, moisture, and contaminants, ensuring the product remains in pristine condition. The clean, professional appearance enhances shelf appeal and supports premium retail pricing by conveying quality and reliability at first glance.

3. How long does custom toy packaging take?

Standard production typically takes 3–4 weeks, while custom tooling requires an additional 5–7 days after mold or proof approval before full production begins. Rush orders can sometimes be accommodated for an additional fee, but planning ahead is always the best way to ensure timely delivery—especially for new product launches or seasonal releases.

4. What is the minimum order for custom packaging?

Most suppliers require 2,500 to 10,000 pieces as a minimum for custom packaging projects, though standard sizes may be available in smaller quantities. Volume pricing provides significant cost savings as order quantities increase, making larger runs more economical. Sample quantities can also be produced for testing, fitting, and final approval before full-scale production begins.

5. Can blister packaging handle different toy sizes?

Yes, the system accommodates a wide range of toy dimensions through custom-engineered cavity designs that keep products securely in place and protected from movement or damage. Durable materials are selected to withstand sharp edges, points, or delicate components, ensuring both safety and product integrity. Additionally, adjustable tooling systems allow for quick changeovers between different sizes and styles, making production efficient and versatile for diverse toy lines.

6. Where can I buy quality toy blister packaging?

Quality packaging is best sourced from established manufacturers and specialized suppliers who understand the unique requirements of the toy industry and provide expert support throughout production. POWERPAK Industries stands at the forefront of this market, offering high-performance packaging systems known for their reliability, consistency, and precision—trusted by leading brands for delivering professional results every time.

CATEGORY

Product Packaging, Retail Packaging

LAST UPDATED

November 19, 2025